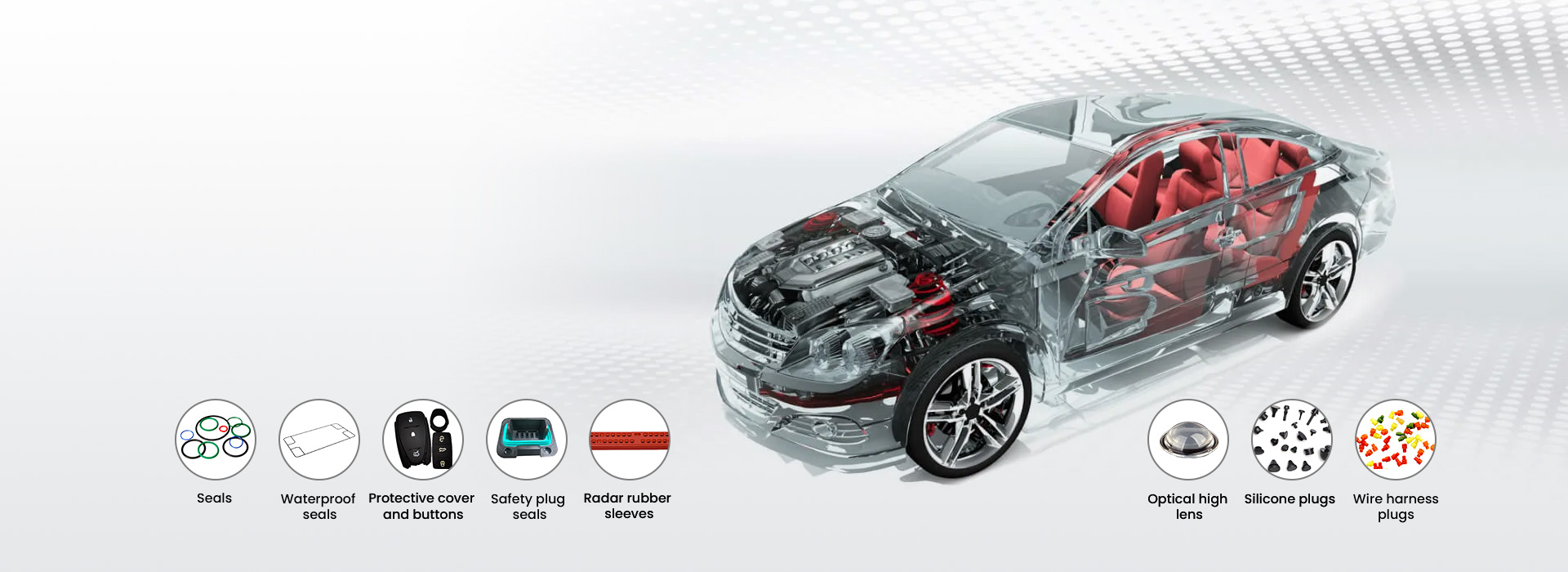

Silicone Overmolding Manufacturing Solutions for Different Industries

Silicone OverMolding Manufacturing Solutions

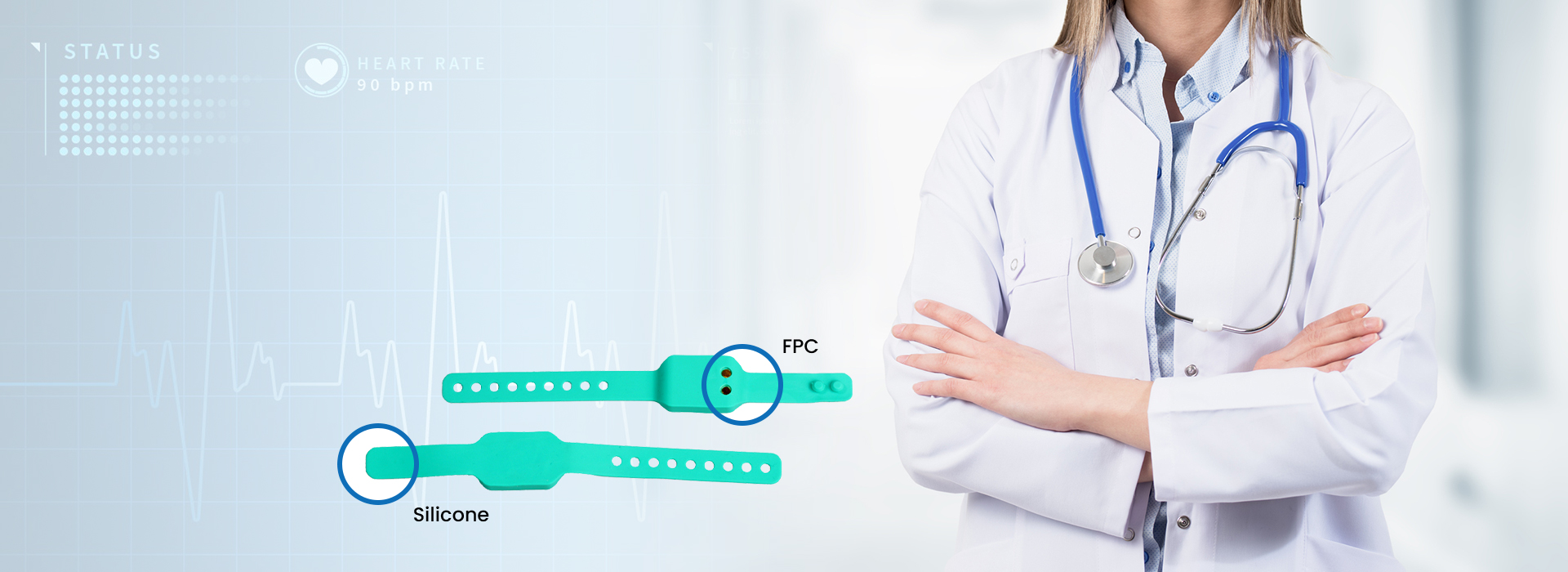

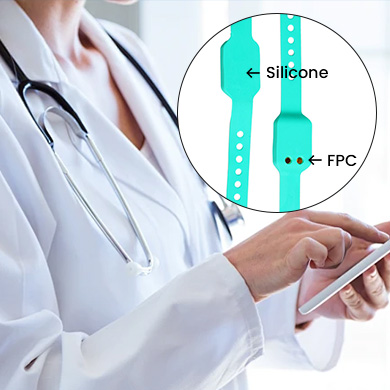

Silicone has excellent flexibility, high temperature resistance and waterproof properties. When combined with FPC, it can provide products with higher stability and durability.

Liquid silicone is precisely molded, with a protection level of up to IP68, and is the first choice for waterproof sealing in the electronics industry.

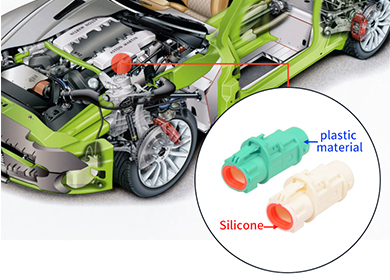

The new silicone-in-plastic process perfectly combines silicone and plastic to create stronger, more durable and more flexible products.

Soft and durable silicone materials are wrapped together to form a composite material with multiple excellent properties.

Bring Your Vision to Life: Free Samples & Free Consultation Service

Business Partnership Model

Trading Company

- Silicone in high demand

- One-on-one customized service

- Fast delivery

- Quick Quote and Sample Delivery Service

Silicone OverMolding Manufacturing Process

1

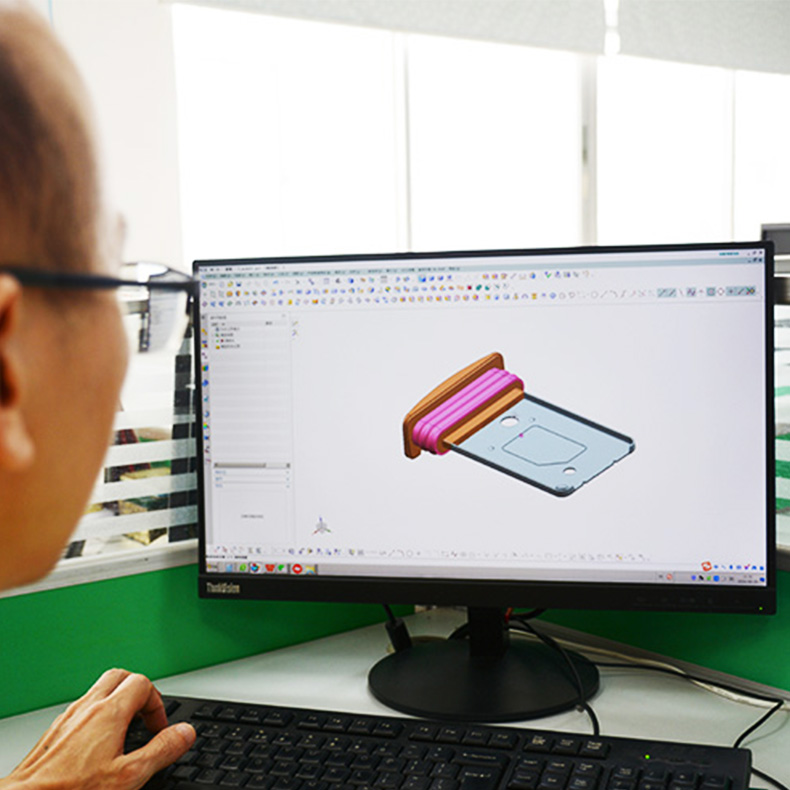

According to customer needs and requirements, we provide innovative and practical product design solutions. Our design team can tailor the most suitable solution for you and ensure the perfect presentation of the design.

2

We have our own silicone mold making capabilities, equipped with high-end equipment and a professional team, and are committed to providing customers with high-quality, high-performance customized silicone mold solutions.

3

Whether your silicone product needs are mass production or small batch customization, we can provide you with the best solution.

Ability of SiliconePlus

We're a leader in silicone customization, with a 24-year history. Renowned for our specialization, efficiency and innovation, we're committed to making integrated silicone and other materials products. Our product range is wide, including custom solutions for silicone and FPC, metal, plastic, magnets and other silicone rubber structural parts. For waterproofing or other needs, our products meet IP67, the highest industry standard. In manufacturing, we use a unique solid-to-liquid integrated molding process, having obvious mold cost advantages over common liquid silicone injection molding. Plus, our process is more flexible, enabling custom production of one piece. Our team is composed of experienced and skilled professionals like silicone mold design engineers, CNC machining technicians and mold debugging engineers. They have rich experience and deep knowledge in silicone mold making to offer high-quality custom services.

Experience

23 years of silicone customization factory

Reputation

The choice of customers such as OPPO, Luxshare, ZARA, etc.

Technology

Silicone + other materials one-piece molding

Waterproof Level

The highest waterproof level is IP67

Cost

One-piece molding mold cost advantage

Customization

Flexible production, one piece can be customized

Customer Cases

OPPO

Lift camera waterproof silicone ring

The silicone coating of OPPO's product represents the first waterproof project for the lifting camera of high-end mobile phones. The challenge was to achieve a high waterproof level using silicone coating on powder metallurgy polished electroplated products, all while preserving the product's pristine appearance. Competitors eventually gave up due to the complexity, but we remained committed and successfully broke through the technical barriers. As a result, we secured 90% of the orders and elevated the waterproof standard for 3C products from IP65 to IP67. This achievement not only showcased our expertise but also set a new industry benchmark for future innovations.

HFY

New ECG monitoring patch

HFY needed to develop a new ECG monitoring patch. We selected medical-grade high-softness silicone, which meets medical standards and is flexible and comfortable. We worked with suppliers to customize high-conductivity FPC and developed a special injection molding process. After multiple tests, we adjusted and optimized the parameters to ensure that the silicone perfectly covered the FPC without bubbles or delamination. The product was well received by doctors and patients and achieved excellent sales performance.

Waterproofing Problem

Waterproof automotive connector

As new energy vehicles develop, connector waterproof performance is vital. A manufacturer experienced circuit failures in humid conditions due to poor waterproofing, impacting safety.

Key Issues:

Insufficient waterproofing: Connectors short-circuit in humid environments.

Durability: Stability required in extreme conditions.

Customization: Complex models need tailored solutions.

Our Solution:

Efficient waterproofing: High-quality silicone meets IP68 standards.

Improved durability: Tested for extreme environments.

Custom production: Designed for specific needs, ensuring quality and efficiency.

Beauty and health care silicone processing case

Solve customer needs and improve product competitiveness

With the development of the beauty and health care industry, consumers' demand for high-quality, safe and beautiful products continues to increase. A well-known beauty brand encountered a problem when developing high-end beauty equipment: it needed a soft and durable silicone shell that would not irritate the skin while ensuring high-end appearance and antibacterial properties, but it had not found a suitable supplier.We use high-end medical-grade silicone to ensure softness, non-toxicity and antibacterial properties. Through precision mold design and processing, we ensure that the product meets high-end appearance requirements and has durability. We deliver on time and provide follow-up technical support to meet customer needs.

Trusted by Over 3000+ Global Clients

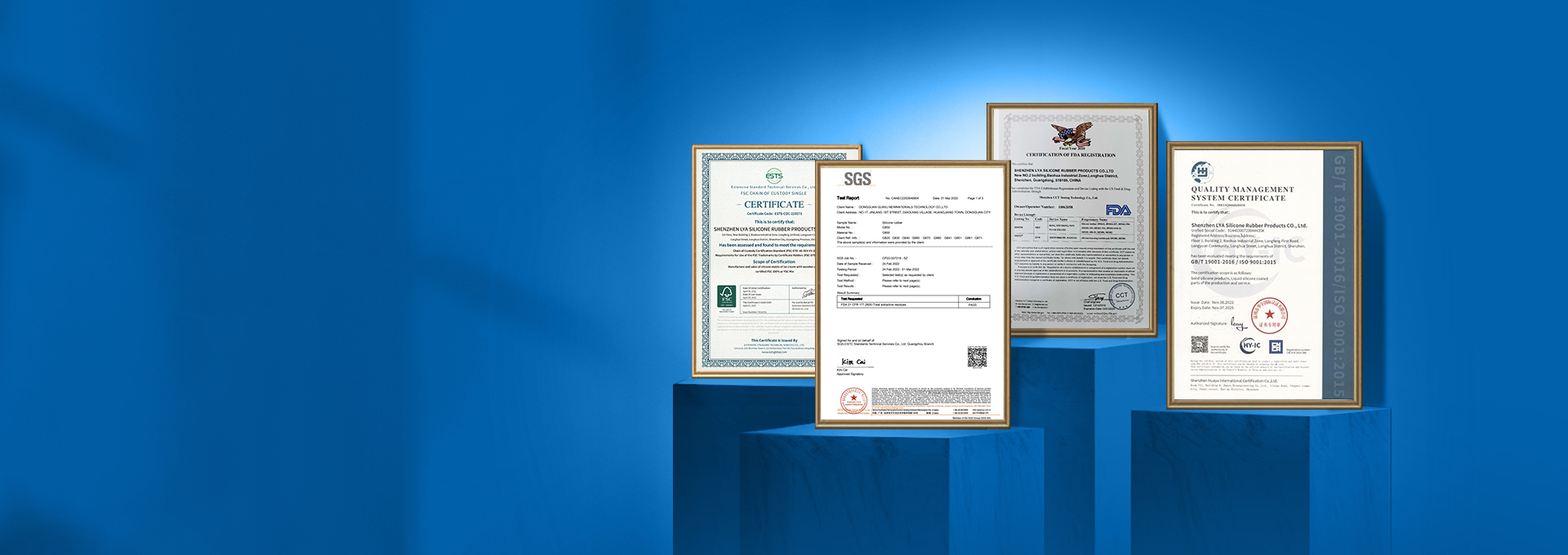

Qualifications and Honors

Our Partners

Mold and Sample Acquisition

Our customer service is online 24/7 to provide you with professional advice.

- Rapid Prototype

- Free consultation service

- Free similar samples for referance

- DFM report

Requirements Analysis and Solutions

Based on your specific needs and project requirements, we will provide you with customized solutions to best meet your needs.

Free DFM reportQuick Quote

Contact us to quickly provide you with better silicone and plastic product prototypes.

Quick Quote