23 years of manufacturing experience

23 years of focus on silicone customization, rich manufacturing experience and superb craftsmanship to provide you with the best quality products.

23 years of focus on silicone customization, rich manufacturing experience and superb craftsmanship to provide you with the best quality products.

Customers such as OPPO, Luxshare, and ZARA choose us not only because of our high-quality products and advanced technology, but also because of our consistent service concept and accurate grasp of customer needs.

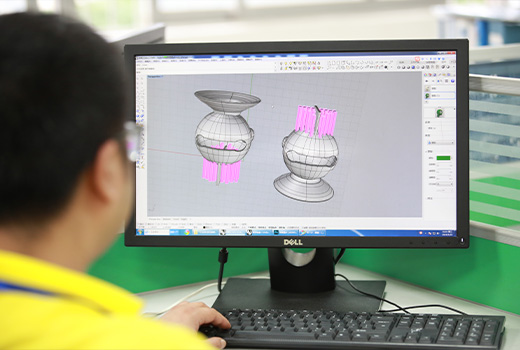

We have unique advantages in the one-piece molding technology of silicone and other materials. We can perfectly combine silicone with metal, plastic, ceramic and other materials to enhance the functionality and durability of the product.

Excellent waterproof performance, waterproof level reaches IP67, can completely prevent dust from entering, and can be immersed in 1 meter deep water for 30 minutes without being affected.

By optimizing mold design and manufacturing processes, we provide customers with high-quality, low-cost mold solutions, greatly reducing mold costs while shortening production cycles, helping customers bring products to market faster.

We have a flexible production line and an efficient management system, which can carry out flexible production according to customer needs. Whether it is mass production or small batch customization, we can respond quickly and provide high-quality products.

Our customer service is online 24/7 to provide you with professional advice.

Based on your specific needs and project requirements, we will provide you with customized solutions to best meet your needs.

Free DFM reportContact us to quickly provide you with better silicone and plastic product prototypes.

Quick Quote

86-13420974883