There are drawings

If you have drawings, SiliconePlus can create the mold directly.

If you have drawings, SiliconePlus can create the mold directly.

Send us your plastic sample and Silicone Plus can make the mold for you directly.

If you only have a drawing, SiliconePlus can directly produce the mold for you.

If you only have the idea of making silicone products, you can tell us directly and SiliconePlus can make it happen for you.

We communicate with you to understand product functionality, appearance and performance requirements.

Based on your needs, we formulate a design plan combining silicone + FPC, including circuit board structure rationality analysis, silicone shape, material selection, etc.

According to the application scenario and requirements of the product, select the applicable silica gel type, including liquid silica gel and solid silica gel.

Consider the flexibility, high temperature resistance, waterproofness and other performance requirements of the product, and select silicone materials that meet the requirements.

Give priority to environmentally friendly silicone materials to ensure that products comply with environmental standards and requirements.

Select silicone material suitable for plastic, prepare silicone and add appropriate vulcanizing agent and catalyst.

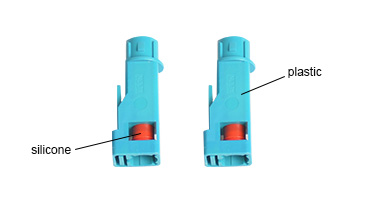

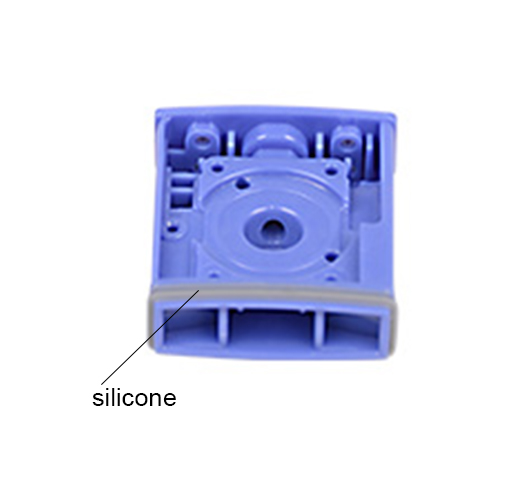

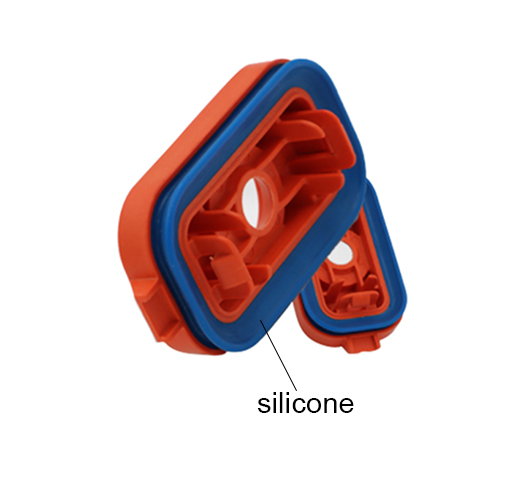

Inject silicone into the mold, place the plastic in the mold, and ensure that the silicone fills the space around the plastic.

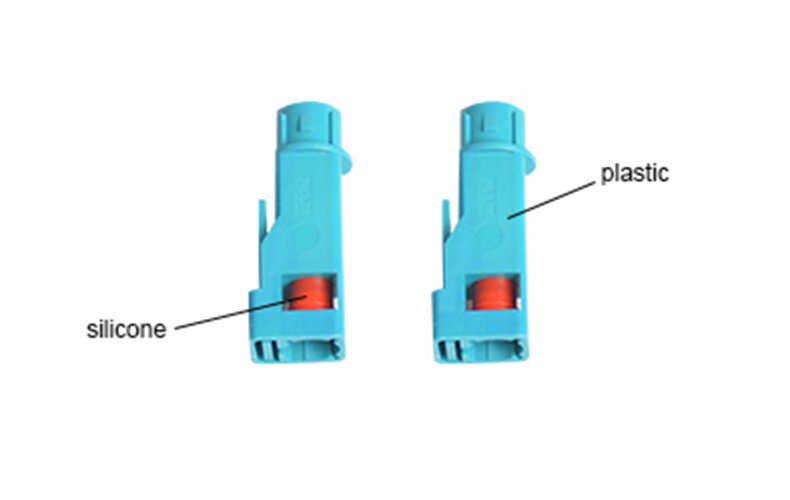

After curing and processing steps, it is ensured that the silicone and plastic form a strong bond and the final form of the product is achieved.

Select silica gel material suitable for plastic, prepare silicone and add appropriate vulcanizing agent and catalyst.

Choose high temperature resistant silicone material to ensure that the product is stable and reliable in high temperature environments.

Ensure that the circuit connection and signal transmission performance of silicone + plastic products are good and are not affected by the silicone material.

Silicone has good waterproof and dustproof properties and can protect the plastic circuit board from the external environment.

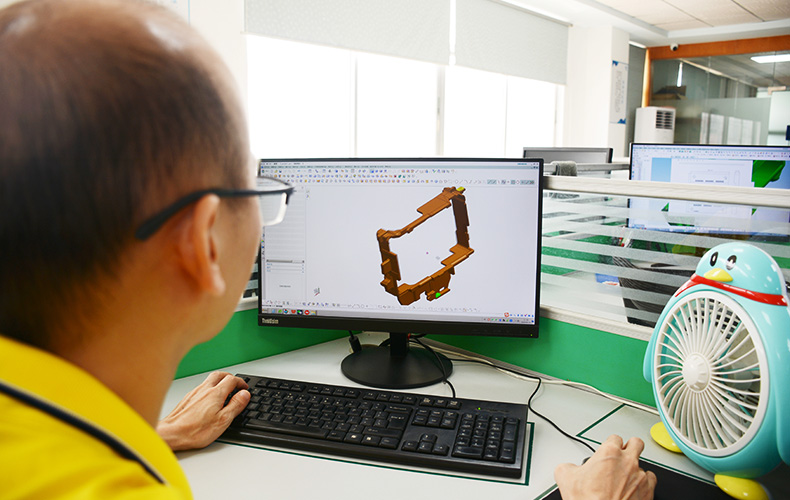

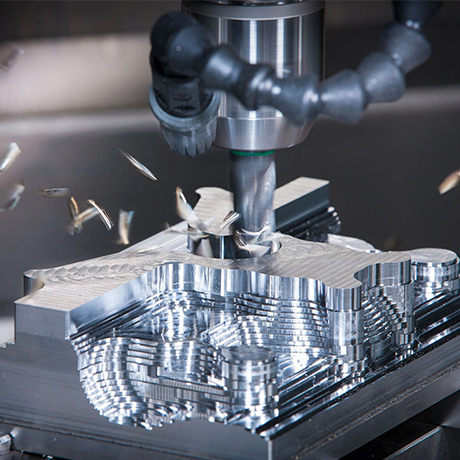

According to the product design plan and requirements, design and make molds suitable for silicone injection molding to ensure precision and stability.

Develop the production process and process parameters to ensure that each link can proceed smoothly and achieve the expected results.

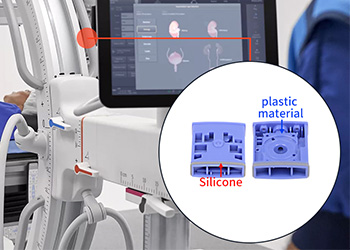

We combine the flexibility of silicone with the strength of plastic to deliver products that offer exceptional durability, comfort and aesthetics for a wide range of industry applications.

Silicone and plastic combine in car electronics to connect components like sensors, meeting complex environmental needs. Silicone overmolding or coating provides high temperature resistance, aging resistance, and flexibility for reliable performance.

Silicone over plastic products can improve the comfort, stability and durability of medical sensors and devices. Silicone materials have properties such as high temperature resistance, flexibility and biocompatibility, and can provide customized solutions to improve the performance and competitiveness of medical products.

In industrial robots, sensors and other equipment, the silicone-coated plastic process enables the product to achieve the connection and protection of flexible circuits, improving the intelligence and stability of the equipment.

A well-known high-end electronic product manufacturer wanted to customize a durable, lightweight and comfortable shell for its new smart device. The customer required the shell to have excellent protection and provide a unique texture, while ensuring the assembly accuracy of precision parts in a complex structure.

The customer's requirement is to use plastic as the main material, but in order to improve the durability and protection of the shell, they want to add a layer of silicone on the outer layer, which can increase the anti-fall and anti-slip effect. At the same time, the shape of the device shell is complex, requiring very high precision and seamless integration.

We use advanced silicone plastic processing technology combined with professional mold design to provide customers with solutions that meet their needs. Through precise injection molding and silicone coating technology, we ensure that the silicone layer is perfectly integrated with the plastic substrate, not only achieving the expected protection performance, but also maintaining a comfortable feel.

Material selection:We chose medical-grade high-softness silicone, which not only meets medical standards but also has excellent flexibility and comfort. At the same time, we worked with suppliers to customize a highly conductive plastic to ensure its perfect combination with silicone.

Process development:We developed a special injection molding process for the combination of silicone and plastic. Through multiple trials and adjustments, we optimized the injection molding parameters to ensure that the silicone can completely cover the plastic without any bubbles or delamination.

Sample testing:After the initial success, we made a batch of samples and worked with medical companies to conduct rigorous performance tests. These tests include long-term wear tests, signal conduction tests, and biocompatibility tests. The results show that our products perform well in all tests.

Mass production:Based on the successful sample testing, we further improved the production process and put it into mass production. We have established a strict quality control process, and each batch of products is fully inspected to ensure that every ECG monitoring patch that leaves the factory meets the highest standards.

Through our efforts, the medical company successfully launched a new ECG monitoring patch. This product has not only been well received by doctors and patients, but also achieved excellent sales performance in the market. The leadership of the medical company highly praised our professional ability and cooperative attitude, and expressed their willingness to continue to cooperate with us in the future to develop more innovative medical products.

This successful product development case demonstrates our expertise and innovative spirit in silicone + metal processing. As a professional custom silicone product manufacturer, we will continue to be committed to providing customers with high-quality and innovative solutions and contributing to the development of the medical industry.

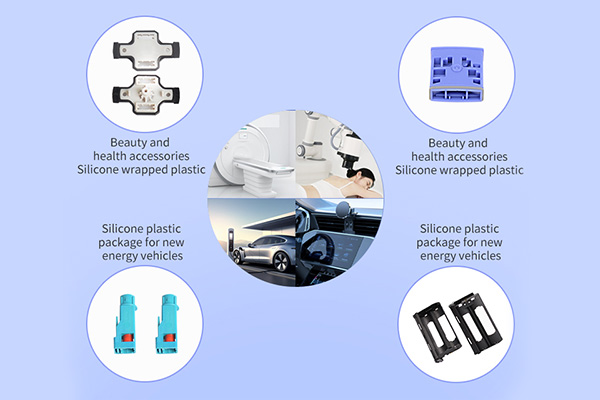

Silicone waterproof female connector to RG58 RF HD camera car connector silicone rubber waterproof

Learn more

Liquid Silicone Rubber Coated Plastic Beauty Equipment Parts Processing Factory

Learn more

Customized precision new energy vehicle silicone encapsulated liquid silicone injection mold

Learn more

Liquid silicone rubber injection silicone rubber car connector silicone waterproof

Learn more