There are drawings

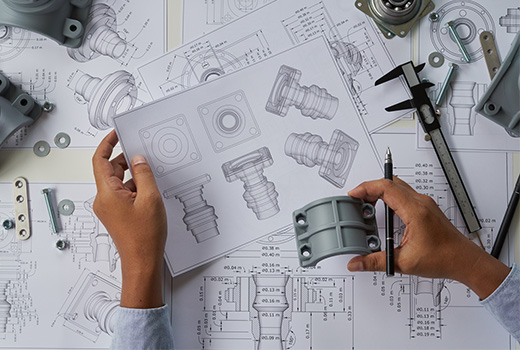

If you have drawings, SiliconePlus can create the mold directly.

If you have drawings, SiliconePlus can create the mold directly.

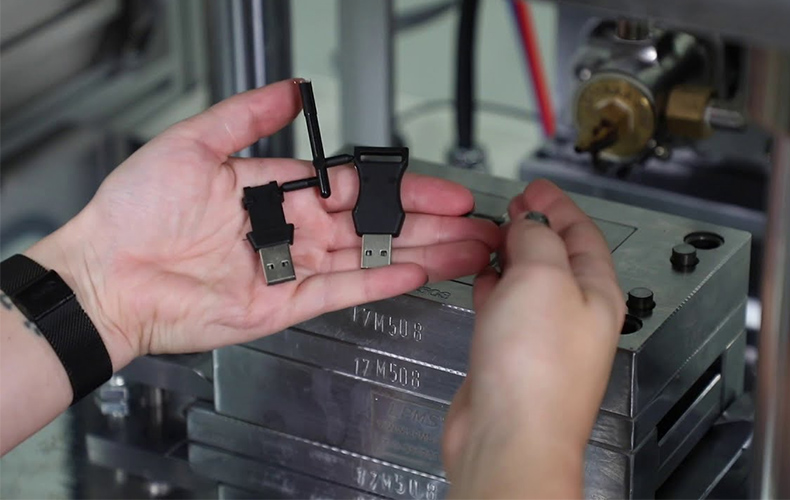

Send samples of plastic, FPC, metal parts, etc. to us and SiliconePlus can directly open the mold for you.

If you only have the structural drawings of the metal parts, SiliconePlus can directly produce the mold for you.

If you only have the idea of making silicone products, you can tell us directly and SiliconePlus can make it happen for you.

We communicate with you to understand product functionality, appearance and performance requirements.

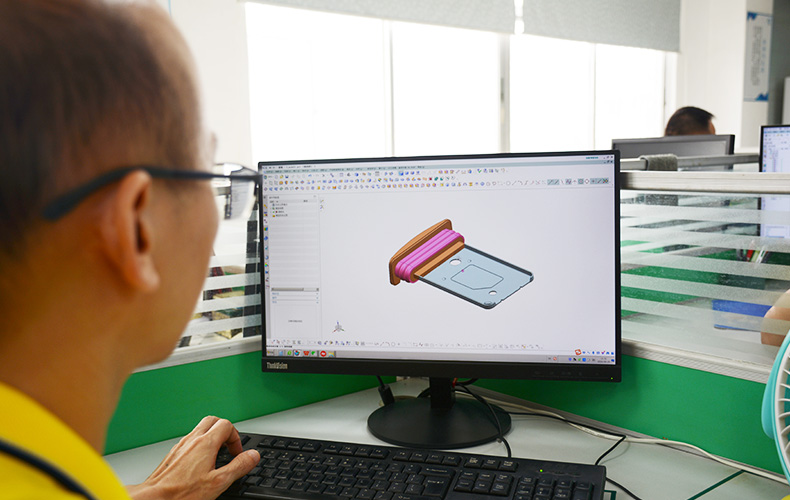

Based on your needs, we formulate a design plan combining silicone + FPC, including circuit board structure rationality analysis, silicone shape, material selection, etc.

According to the application scenario and requirements of the product, select the applicable silica gel type, including liquid silica gel and solid silica gel.

Consider the flexibility, high temperature resistance, waterproofness and other performance requirements of the product, and select silicone materials that meet the requirements.

Give priority to environmentally friendly silicone materials to ensure that products comply with environmental standards and requirements.

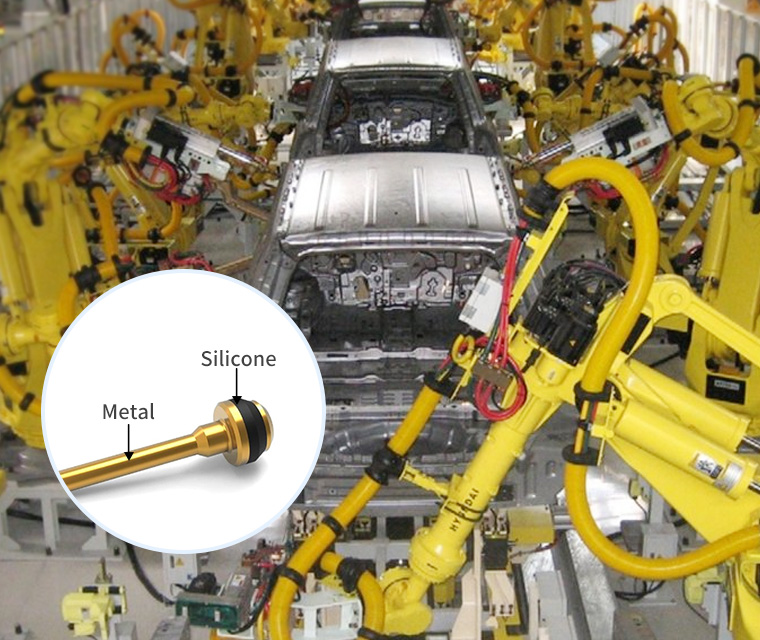

Select silicone material suitable for bonding to metal, formulate silicone and add appropriate vulcanizer and catalyst.

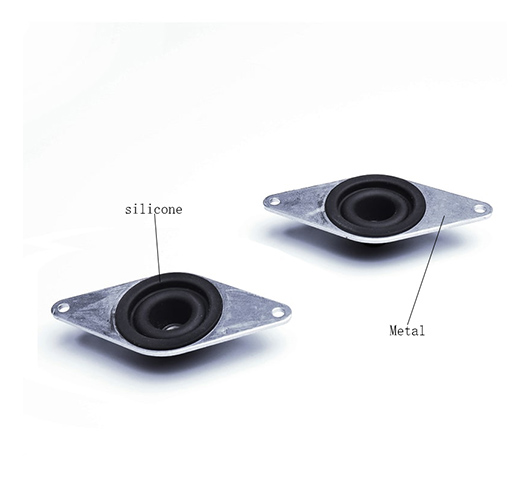

The silicone is injected into the mold and the metal part is accurately placed inside the mold. The silicone will then completely envelop the metal part, ensuring that every space around it is filled, thus achieving excellent physical properties and durability.

After the curing and processing steps, it is ensured that the silicone and metal form a strong bond and achieve the final shape of the product.

Select the silicone material suitable for the metal, formulate the silicone and add appropriate vulcanizing agent and catalyst.

Choose high temperature resistant silicone material to ensure that the product is stable and reliable in high temperature environments.

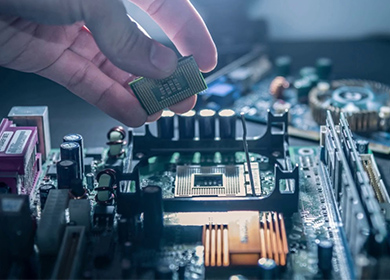

Ensure that the circuit connection and signal transmission performance of silicone + metal products are good and are not affected by the silicone material.

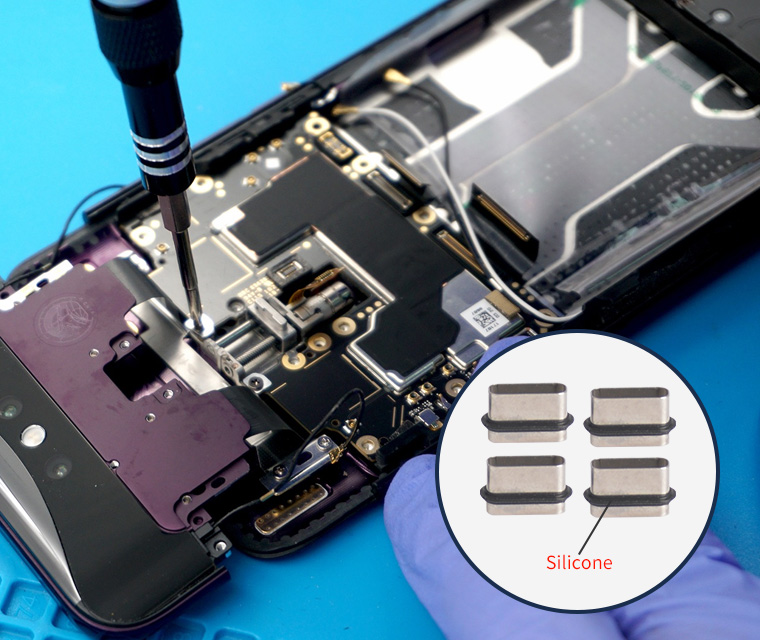

Silicone has good waterproof and dustproof properties and can protect the product from the influence of the external environment.

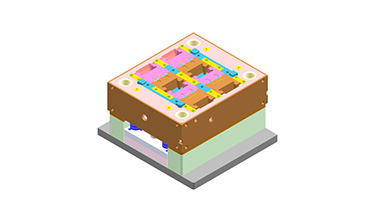

According to the product design plan and requirements, design and make molds suitable for silicone injection molding to ensure precision and stability.

Develop the production process and process parameters to ensure that each link can proceed smoothly and achieve the expected results.

Consumer electronics: such as smartphones, tablets, etc., silicone + metal products can be used to protect circuit boards and metal parts, enhancing the stability and durability of the equipment.

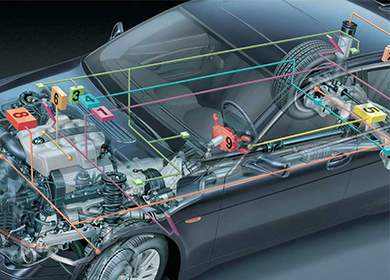

In automotive applications, silicone + metal is often used in seals, shock absorbers, electrical connectors, engine components and lamp housings. They provide high temperature resistance, vibration resistance, insulation, waterproof and durability protection, improving component performance and service life.

Silicone + matal products can be used in medical sensors and portable medical equipment to improve the comfort and stability of the product.

In industrial robots, sensors and other equipment, silicone + matal products can achieve flexible circuit connection and protection, improving the intelligence and stability of the equipment.

Not long ago, an innovative consumer electronics company approached us. They were developing a new handheld device that required a housing that combined the soft-touch feel of metal and silicone with anti-slip properties. Their goal was to create a product that was both beautiful and practical, offering users a superior grip.

Technological innovation and excellence:After the project started, our team immediately started mold development and material testing. Due to the complex structure of the product, we faced the technical challenge of how to ensure that the silicone was evenly coated without affecting the dimensional accuracy of the plastic parts. After many tests and adjustments, we finally optimized the mold design and adopted the most advanced liquid silicone injection process, which made the silicone and plastic parts perfectly integrated under high temperature and high pressure, which not only improved the appearance and texture of the product, but also enhanced its durability and comfort.

From scratch to mass production: Delivering a product that exceeded expectations: Throughout the project, we maintained close communication with the client, providing timely feedback on every production progress and process improvement. After multiple rounds of sample testing and adjustments, we ultimately successfully transformed the client's idea into reality. The customized silicone-coated metal product not only met the client's expectations in appearance but also exceeded their functional expectations.

When we delivered the first batch of mass-produced products to our customers, they praised the quality and feel of the products. This product was ultimately highly recognized by the market, helping customers stand out in the fierce market competition.

Mold development: Faced with complex product structures, we developed an optimized mold design to ensure that the silicone can be evenly coated on the surface of the plastic parts without affecting the dimensional accuracy of the plastic parts.

Material selection and testing: We selected the most suitable liquid silicone material and conducted multiple tests to ensure that it can be perfectly integrated with the plastic, while meeting the customer's expected feel and appearance requirements.

Liquid silicone injection molding: Using advanced liquid silicone injection molding technology, the silicone is closely combined with plastic parts under high temperature and high pressure environment to ensure the consistency of the coating effect and the durability of the product.

Strict quality control:During the production process, we strictly control every link, from the selection of raw materials to the inspection of finished products, each step meets high standards of quality requirements to ensure the quality and reliability of the final product.

From creativity to mass production: We provide a complete set of comprehensive solutions from design consultation, mold development, material selection to production process implementation, which not only solves technical problems, but also optimizes time and cost.

Customer customization experience: The entire process provides customers with a flexible and transparent customization experience, so that the final product can perfectly match the customer's market needs and brand positioning.

This solution demonstrates our factory's innovation and professionalism in dealing with complex customization requirements, ensuring that every step meets or even exceeds customer expectations.

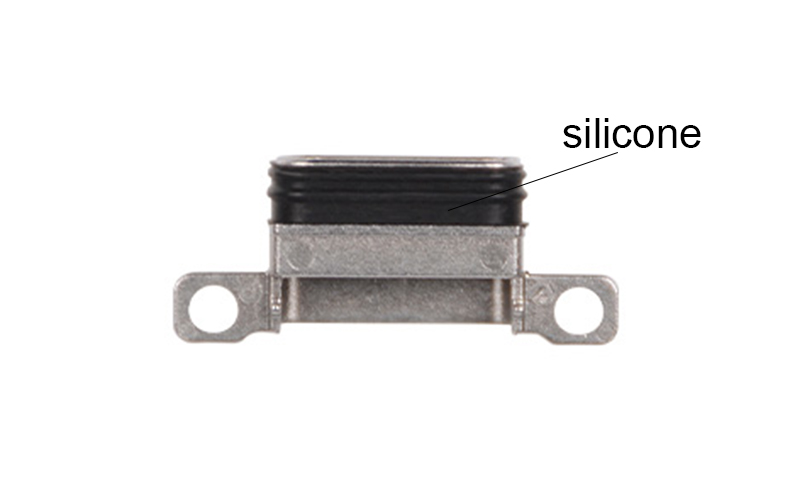

Mobile phone side button waterproof silicone accessories

Learn more

Type-c waterproof female mobile phone tail plug connector silicone overmolding

Learn more