High Precision & Repeatability

Perfect for intricate designs and small, detailed parts.

Perfect for intricate designs and small, detailed parts.

High-temperature resistance, biocompatibility, and superior durability.

Shorter production cycles and waste reduction for optimized results.

Tailored to meet your unique product requirements across industries.

Custom Silicone Manufacturer – Precision Liquid Silicone Injection Molding Solutions

Quote Now

From medical devices (seals, gaskets, implants) to automotive components (sensors, connectors) and consumer electronics (wearables, waterproof seals), our custom silicone solutions meet stringent requirements for durability, biocompatibility, and extreme environments.

Quote Now

We use advanced silicone overmolding technology to perfectly combine liquid silicone with metal, plastic, FPC and other materials to meet the special needs of the new energy vehicle field.

Quote Now

Siliconeplus focuses on the customized production of waterproof silicone encapsulation for battery covers of 3C electronic consumer products, providing customers with high-performance protection solutions to comprehensively improve the sealing, durability and design aesthetics of the products.

Quote Now

Siliconeplus focuses on providing high-quality silicone accessories for the industrial field. Through advanced technology and innovative processes, it empowers customers' products and helps them achieve excellent performance in complex application scenarios.

Quote Now

This detachable mask accessory features a large flap structure that perfectly matches the face seal, making it suitable for long-term wear

Quote NowLSR is a thermosetting material with excellent fluidity and can be precisely molded in high-precision and complex molds. Siliconeplus focuses on the research and development and production of LSR precision silicone products, and is committed to providing customers with high-quality, high-performance customized solutions.

The liquid silicone encapsulation process combines liquid silicone with materials such as plastics and metals. Through hot pressing molding technology, the product has excellent high temperature resistance, anti-aging, chemical corrosion resistance, excellent elasticity and biocompatibility. This process has been widely used in many industries, especially in the fields of automobiles, electronics, medical, consumer products, etc., which can effectively improve the durability and functionality of products.

As an industry leader, Siliconeplus not only provides standardized LSR products, but also can be customized according to the specific needs of customers. Our professional team will work closely with you to ensure that every link of each project from design to production achieves the best results. Whether it is complex shapes, extremely fine size requirements, or high-standard performance requirements, we can provide precise solutions.

Each LSR product passes strict quality control to ensure compliance with international certification standards.

Our R&D team has rich experience and can quickly transform innovative designs into mass production.

Provide precise material, size, color and function customization according to customer needs to meet the challenges of various application scenarios.

Whether you need to improve the performance of existing products or develop new products, Siliconeplus can provide you with reliable LSR technical support and efficient production solutions to help you stand out in the fierce market competition.

In the 3C electronics industry, our liquid silicone injection molding solutions are essential for components like:

Ensuring IP68-level protection for smartphones from brands like Huawei and Xiaomi.

Enhancing user experience with long-lasting, flexible, and sealed silicone parts.

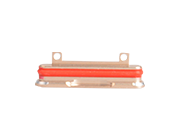

Customer:A global smartphone brand.

Challenge:Needed a durable, high-precision waterproof card tray that could meet IP68 waterproof requirements.

Solution:Using our liquid silicone injection molding technology, we created a seamless, robust, and lightweight card tray with perfect waterproof properties. The solution helped the customer meet international waterproofing standards while achieving a competitive edge in the market.

In the medical industry, our expertise in liquid silicone injection molding ensures top-tier performance for sensitive applications, such as:

Silicone coating for circuit boards to ensure seamless one-piece molding and medical-grade safety.

Providing hypoallergenic, flexible, and durable solutions for medical devices.

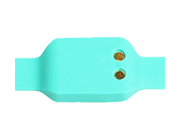

Customer:A manufacturer of children’s temperature monitoring patches.

Challenge:Needed a silicone coating for their circuit boards to ensure dustproof, waterproof, and safe contact with skin.

Solution:Our team developed a biocompatible liquid silicone coating with high precision molding to protect the electronics while maintaining complete safety for skin contact. The result exceeded the customer’s expectations and helped their product meet strict medical-grade compliance standards.

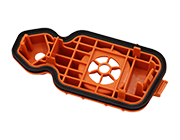

For the automotive industry, our liquid silicone injection molding technology delivers unmatched performance for:

Protecting vital automotive electronics from water, dust, and extreme temperatures.

High-durability solutions designed to withstand the harshest driving conditions.

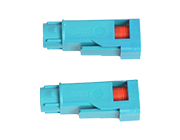

Customer:A global automotive parts supplier

Challenge:The customer needed a high-precision waterproof connector that could protect automotive electronic components from water, dust and temperature fluctuations in extreme temperatures and harsh environmental conditions.

Solution:Through our liquid silicone injection molding technology, we customized a highly durable and waterproof connector for the customer. The combination of liquid silicone and metal contact parts ensures perfect sealing and can withstand extreme environments such as high temperature, low temperature and humidity. This solution not only improves the reliability of automotive electronic systems, but also helps customers reduce maintenance costs caused by connector failures. Ultimately, this product helped the customer improve the market competitiveness of its products and gain recognition from the automotive industry.

We create tailored solutions for your unique application needs.

Mastering the exceptional properties of silicone for unbeatable performance.

Advanced molding techniques to ensure quality and consistency at scale.

Efficient production capabilities to meet tight deadlines.

Reduced production costs with waste-minimizing processes.

Enhanced product functionality and user experience.

Competitive advantage with high-performance, custom-designed components.

We rely on in-house tooling and sophisticated processes to enhance quality, ensuring consistently tight tolerances while providing our customers with the lowest cost of ownership.

During the mold assembly process, we strictly follow the mold assembly requirements to ensure the normal operation of the mold and the quality stability of the product.

Mold trial and mold trial report: We provide mold trial services and provide detailed mold trial reports, including mold performance testing, product quality evaluation, etc., to ensure that the mold meets customer needs and requirements.

Customer satisfaction guarantee: We focus on communication and feedback with customers, and continuously optimize mold design and production according to customer needs and feedback to ensure customer satisfaction and trust.

SiliconePlus has been awarded the Shenzhen Specialized, Specialized and New Small and Medium Enterprises and Innovative Small and Medium Enterprises Certificates for its outstanding technical R&D strength and excellent product quality. This is not only a high recognition of SiliconePlus' past efforts and achievements, but also a strong impetus for its future sustainable development.

Reach out for a free consultation and discover how Siliconeplus can bring your product to life with liquid silicone injection molding.

Experience the quality and precision of our silicone solutions for your industry!

Learn more about our capabilities, industries served, and success stories.

86-13420974883