How Much Does Silicone Molding Cost?

When planning a project that involves silicone molding, cost is often a key concern. People want high-quality results but don’t want to overspend. Understanding the costs involved can help you make informed decisions and budget effectively.

Silicone molding costs typically range from $500 to $5,000, depending on size, complexity, and material quality.

Let’s explore what factors affect silicone mold pricing, why they can be expensive, and how long they last. By the end, you’ll have a clear idea of how to calculate your silicone molding costs accurately.

[Table of contents]

.How much does it cost to make silicone mold?

.Why are silicone molds expensive?

.How long do silicone molds last?

.How do you calculate mold for silicone?

How Much Does It Cost to Make Silicone Mold?

Creating a silicone mold can vary greatly in price. The cost depends on several factors, including the size, design intricacy, and material used.

Making a basic silicone mold costs around $500 to $2,000, while complex or industrial molds can exceed $5,000.

Dive deeper into factors influencing cost

Material Quality:

High-grade silicone, like platinum-cured silicone, costs more but ensures better durability and performance.

Mold Size:

Larger molds require more silicone, which increases material costs.

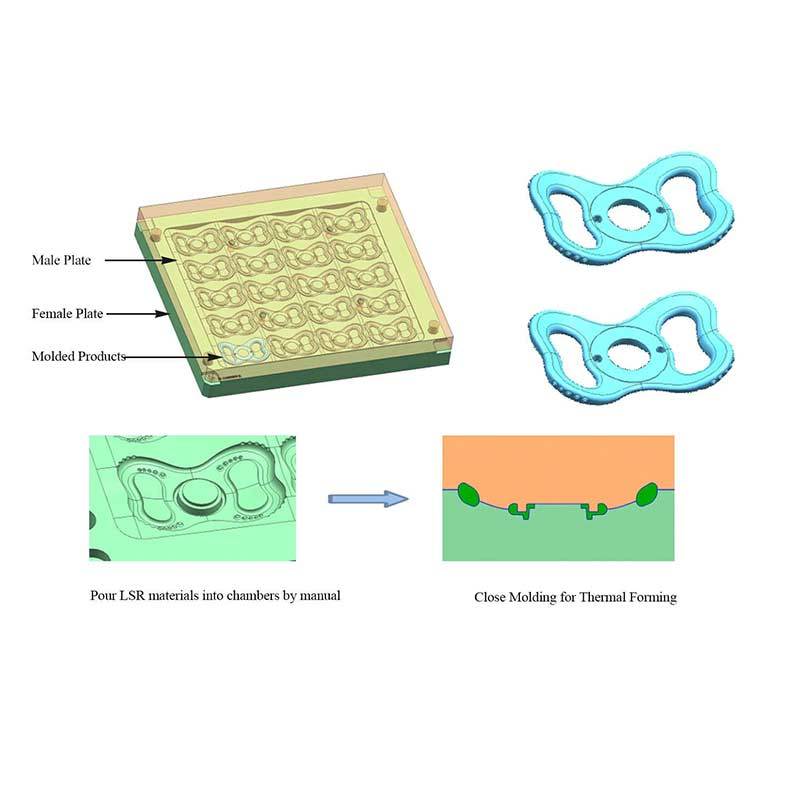

Complexity of Design:

Detailed or intricate molds require more time and expertise to produce. This results in higher labor charges.

|

Factor

|

Impact on Cost

|

Example

|

|

Material Type

|

Platinum > Tin Silicone

|

High-end molds for medical uses

|

|

Mold Dimensions

|

Bigger = Higher Cost

|

Large automotive parts molds

|

|

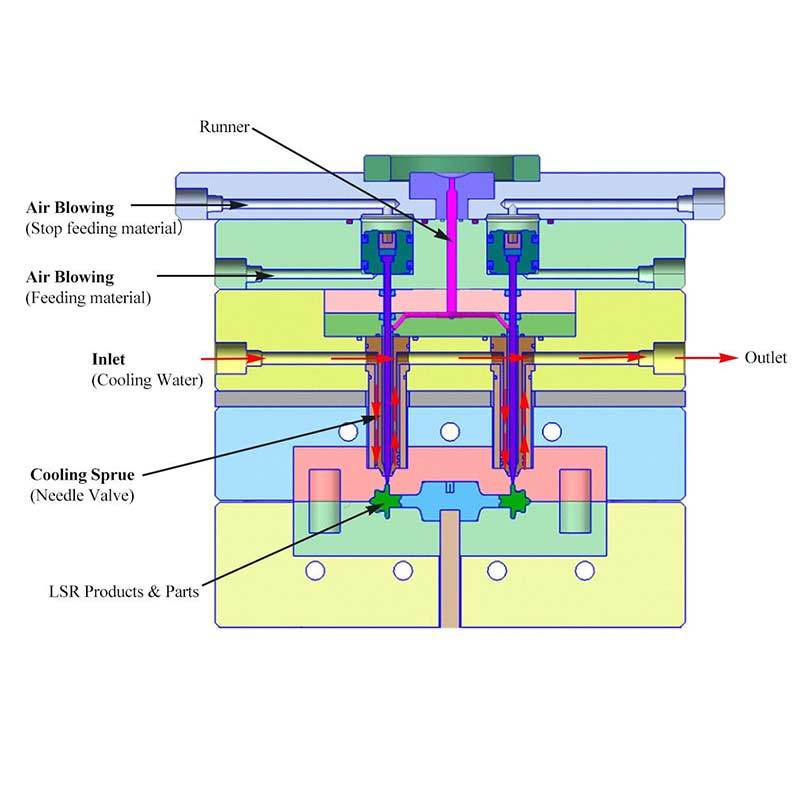

Production Method

|

Hand-made > Machine

|

Custom prototype molds

|

If you’re working on a DIY project, you can save costs by opting for less expensive silicone or smaller mold sizes.

Why Are Silicone Molds Expensive?

Silicone molds are known for their durability, precision, and versatility. However, these qualities often come with a higher price tag.

Silicone molds are expensive due to material costs, production time, and required expertise for precision manufacturing.

Dive deeper into why molds are pricey

Material Costs:

Silicone, especially medical or food-grade, is not cheap. Its unique properties, like heat resistance and flexibility, justify the price.

Labor-Intensive Process:

Skilled technicians need hours to craft, inspect, and perfect molds.

Precision Equipment:

Creating molds requires specialized tools, which adds to overhead costs.

For industries like medical devices or electronics, the upfront expense ensures molds that can withstand repeated use without compromising quality.

Conclusion

Silicone mold costs vary based on size, material, and complexity. By understanding these factors, you can budget more effectively and ensure you get the best value for your investment.