What are the cost advantages of silicone overmolding?

Silicone overmolding is gaining popularity across industries, but is it cost-effective? Understanding its financial benefits can help businesses make informed decisions.

Silicone overmolding reduces costs by improving product durability, minimizing material waste, and streamlining production. It enhances product performance while reducing long-term expenses.

What are the advantages of overmolding?

Overmolding enhances product functionality and durability, making it a preferred choice in various industries.

It improves grip, increases protection against environmental factors, and enhances aesthetic appeal, leading to better user experience and product lifespan.

Improved Durability

Overmolding provides an extra layer of protection, making products resistant to impact, chemicals, and temperature changes. This is particularly useful in medical, automotive, and consumer electronics applications.

Better Ergonomics

By adding soft-touch materials, overmolding improves user comfort and grip, reducing fatigue and enhancing usability.

Enhanced Aesthetic and Branding

Customizable colors and textures allow brands to create visually appealing and unique product designs.

What are the advantages of overmolding?

Overmolding enhances product functionality and durability, making it a preferred choice in various industries.

It improves grip, increases protection against environmental factors, and enhances aesthetic appeal, leading to better user experience and product lifespan.

Improved Durability

Overmolding provides an extra layer of protection, making products resistant to impact, chemicals, and temperature changes. This is particularly useful in medical, automotive, and consumer electronics applications.

Better Ergonomics

By adding soft-touch materials, overmolding improves user comfort and grip, reducing fatigue and enhancing usability.

Enhanced Aesthetic and Branding

Customizable colors and textures allow brands to create visually appealing and unique product

Can silicone be overmolded?

Silicone is a versatile material that can be successfully overmolded onto various substrates.

Yes, silicone can be overmolded onto plastics, metals, and other materials, providing superior flexibility, biocompatibility, and thermal resistance.

Material Compatibility

Silicone adheres well to materials like polycarbonate, ABS, stainless steel, and aluminum, expanding its applications.

Common Applications

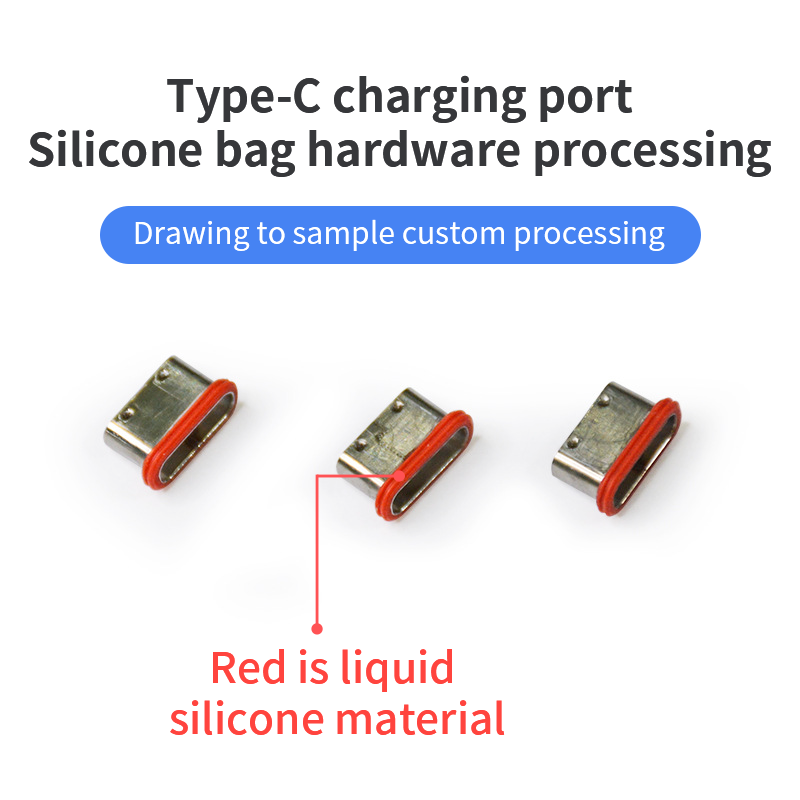

Medical devices: Ensures biocompatibility and sterilization compatibility.

Electronics: Offers waterproofing and shock absorption.

Automotive parts: Enhances temperature and vibration resistance.

How much does it cost for a silicone mold?

The cost of a silicone mold depends on design complexity, material choice, and production volume

A silicone mold can cost between $500 and $10,000, with higher costs for intricate designs and multi-cavity molds.

Factors Affecting Cost

| Factor | Impact on Cost |

| Mold Complexity | More intricate designs cost more |

| Material Quality | High-grade silicone increases durability |

| Production Volume | Higher quantities reduce per-unit cost |

Cost-Saving Tips

1.Optimize mold design to reduce material usage.

2.Use rapid prototyping before committing to full-scale production.

3.Partner with experienced manufacturers to ensure efficiency.

Is overmolding expensive?

Overmolding may have higher initial costs, but it offers long-term savings by improving product durability and reducing assembly time.

While overmolding has higher tooling costs, it lowers labor costs, reduces material waste, and extends product lifespan, making it cost-effective in the long run.

ROI of Overmolding

Lower maintenance costs: Overmolded parts last longer.

Reduced assembly costs: Fewer components mean less manual labor.

Enhanced product value: Higher-quality products reduce warranty claims.

Conclusion

Silicone overmolding offers a strong balance between performance and cost savings. While the upfront investment may be higher, the long-term benefits in durability, efficiency, and user experience make it a worthwhile choice for many industries.