What is the manufacturing process of silicone products?

Silicone products are everywhere, from medical devices to electronics, but understanding how they’re made helps us appreciate their incredible versatility and durability. Let’s explore the processes behind these essential materials.

The manufacturing process of silicone products involves creating silicone from quartz, compounding it with additives, and molding it into final shapes using advanced production techniques.

To fully understand this, we need to dive into the core processes, starting with how silicone and its base materials are made.

Table of contents

.What is the silicone manufacturing process?

.How is silicon made step by step?

.What are the raw materials of silicone?

.What is the manufacturing raw material of silicon?

What is the silicone manufacturing process?

The manufacturing of silicone is a multi-step process that begins with natural minerals and ends with high-performance materials.

Silicone is manufactured by extracting quartz, converting it into silicon, and polymerizing it into flexible silicone rubber, resins, or fluids.

Dive Deeper: Step-by-Step Silicone Manufacturing

Quartz Mining: High-purity quartz is the raw starting material.

Silicon Creation: Quartz is reduced to silicon in electric arc furnaces.

Methyl Chlorosilane Production: Silicon reacts with methyl chloride to form intermediates.

Polymerization: These intermediates are processed into long-chain silicone polymers.

Compounding: Additives, like pigments and stabilizers, are added to customize properties.

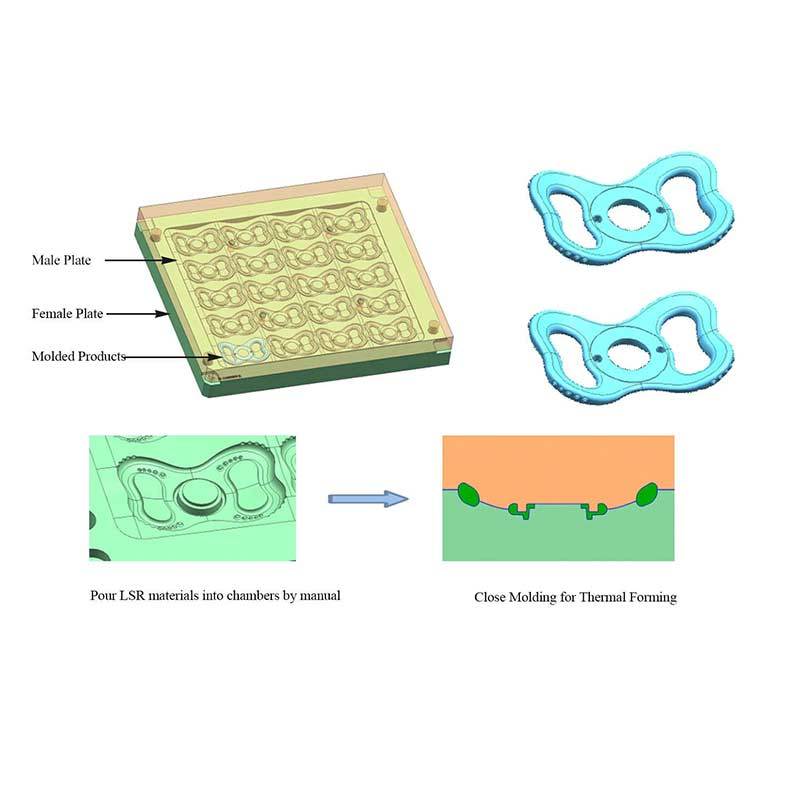

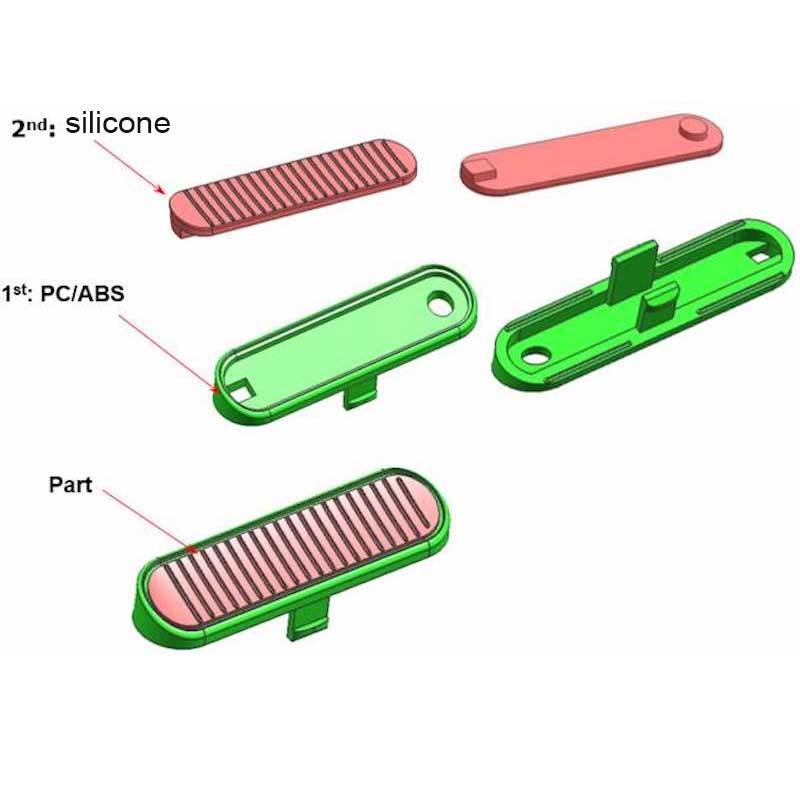

Final Molding: The compounded silicone is shaped into products using injection molding, extrusion, or compression.

These stages are critical for creating the diverse silicone products we use daily, from flexible tubing to electronic seals.

How is silicon made step by step?

Silicon, the building block of silicone, undergoes a rigorous and high-precision creation process.

Silicon is made by reducing quartz in high-temperature electric furnaces, followed by purification to ensure industrial-grade or semiconductor-level quality.

Dive Deeper: The Core Steps of Silicon Production

Quartz Reduction: High-purity quartz is mixed with carbon and reduced in an electric arc furnace at temperatures above 2000°C. This releases oxygen, leaving behind molten silicon.

Crystallization: The molten silicon is cooled and solidified into large blocks or ingots.

Purification: Additional processes remove impurities to achieve up to 99.9999% purity for sensitive applications like electronics.

Quick Fact:Purified silicon is not just used for silicone—it’s essential for microchips and solar panels, showing its wide industrial importance.

What are the raw materials of silicone?

Silicone is an impressive blend of organic and inorganic materials. Understanding these components is key to knowing how silicone gets its unique properties.

Silicone’s raw materials include silica from quartz, methyl chloride, and various catalysts, combined to form versatile polymers.

Dive Deeper: Core Ingredients in Silicone Manufacturing

Silica: Derived from quartz, silica is the foundation of silicone’s inorganic structure.

Methyl Chloride: This compound reacts with silicon to create the precursors for silicone.

Catalysts and Additives: Platinum or tin-based catalysts help speed up reactions, while pigments and stabilizers fine-tune the final material.

These materials combine to form silicone that’s heat-resistant, flexible, and biocompatible, making it ideal for industries like healthcare and electronics.

Properties of Quartz in Silicon Manufacturing:

Property | Importance |

|

High SiO₂ Purity

|

Ensures quality silicon

|

|

Heat Resistance

|

Withstands furnace conditions

|

|

Abundant Availability

|

Economical for large-scale use

|

This reliance on quartz highlights how natural resources are transformed into cutting-edge materials that power modern industries.

Conclusion

The manufacturing of silicone products involves a meticulous blend of chemistry and engineering, starting with quartz and ending with highly adaptable materials. This process enables the creation of everything from medical implants to smartphone components.