What is the molding temperature for liquid silicone rubber?

When working with liquid silicone rubber (LSR), understanding the right molding temperature is crucial for ensuring quality, durability, and efficiency. Without it, production issues or material defects may arise. Let’s uncover the science behind these temperatures.

The typical molding temperature for liquid silicone rubber is between 120°C to 200°C, depending on the specific formulation and application requirements.

Liquid silicone rubber curing relies heavily on precise temperature control, which also varies based on mold design, material thickness, and production speed. Below, we’ll break this topic into critical questions and explore them further.

[Table of contents]

.What temperature does liquid silicone rubber cure at?

.What temperature is silicone molding done?

.What is the temperature range for silicone rubber?

.What is the temperature for rubber molding?

What temperature does liquid silicone rubber cure at?

The curing process of liquid silicone rubber is influenced by heat and time. But what is the specific temperature it needs?

Liquid silicone rubber typically cures at 120°C to 200°C, with higher temperatures shortening curing time.

Dive deeper: What factors affect curing temperature?

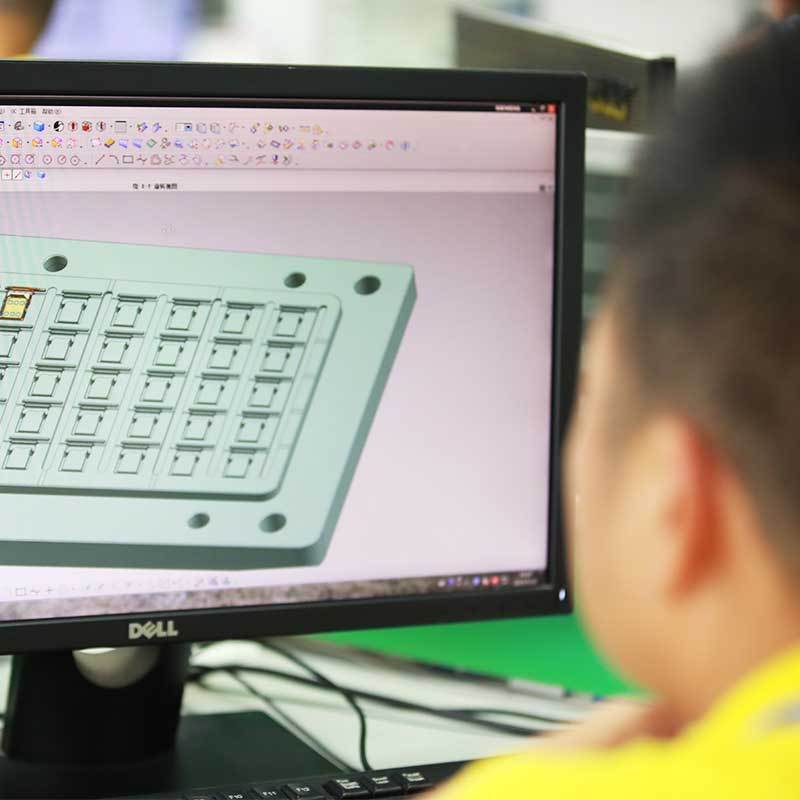

Material composition: Different formulations of liquid silicone rubber may require slight adjustments in curing temperatures. Platinum-cured silicone, for example, needs precise thermal conditions.

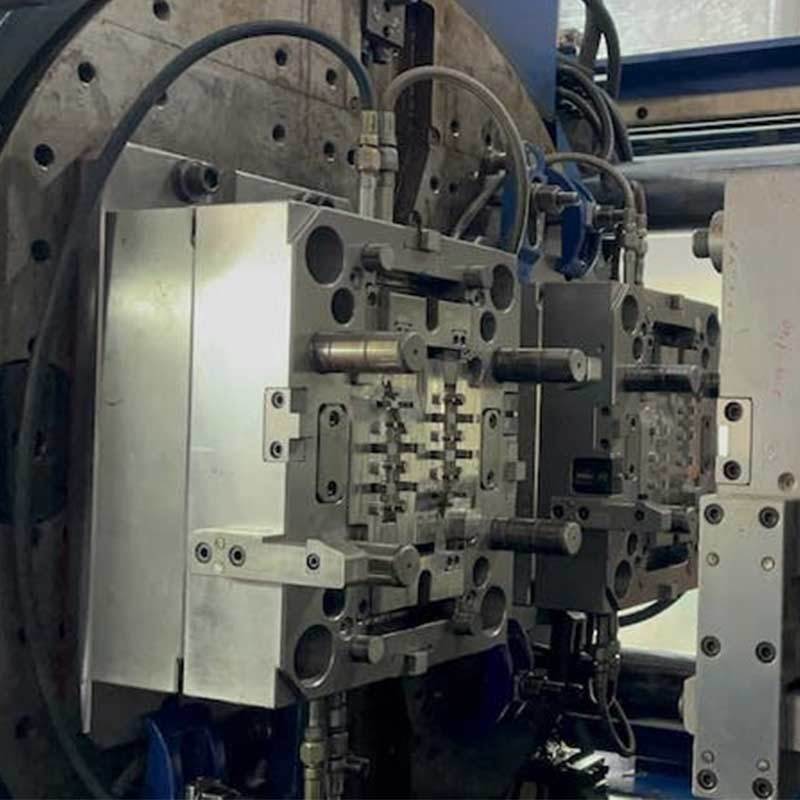

Mold design: Intricate molds with thin walls may require faster curing cycles at higher temperatures, while thicker molds may need more controlled conditions to avoid thermal stress.

Equipment and process optimization: Automated machines often provide controlled heat zones to ensure uniform curing, which affects temperature distribution.

|

Temperature (°C) |

Curing Speed

|

Common Applications

|

|

120°C–140°C

|

Slow

|

Medical-grade components

|

|

150°C–170°C

|

Moderate

|

Consumer electronics

|

|

180°C–200°C

|

Fast

|

Automotive and industrial uses

|