What is the most common material used in injection molding?

What material dominates the world of injection molding?

Thermoplastics are the most common materials used in injection molding due to their versatility and reusability.

Thermoplastics like ABS, polycarbonate, and polypropylene are used across industries, from automotive to electronics. Their recyclability makes them sustainable options.

Dive Deeper: Why thermoplastics?

Properties that stand out

Heat resistance: Thermoplastics handle high temperatures during molding.

Design flexibility: They can be molded into intricate shapes.

Cost-effectiveness: Their reusability reduces material waste.

Comparing thermoplastics and silicone for molds

While thermoplastics excel in injection molding for solid products, silicone shines in applications requiring elasticity or biocompatibility.

What are the raw materials of silicone?

How is silicone created, and what makes it unique?

Silicone is made from silica (sand), carbon, and oxygen, combined with other organic elements to enhance properties.

This combination gives silicone its heat resistance, flexibility, and chemical stability.

Dive Deeper: Understanding the chemistry

Silicone: The base element

Silicone, a natural compound found in sand, forms the core of silicone’s structure.

Additional organic compounds

Carbon and oxygen, along with optional additives like platinum or peroxide, create versatile silicone compounds for specific applications.

What are silicone molds made of?

Silicone molds are known for their durability, but what exactly are they made of?

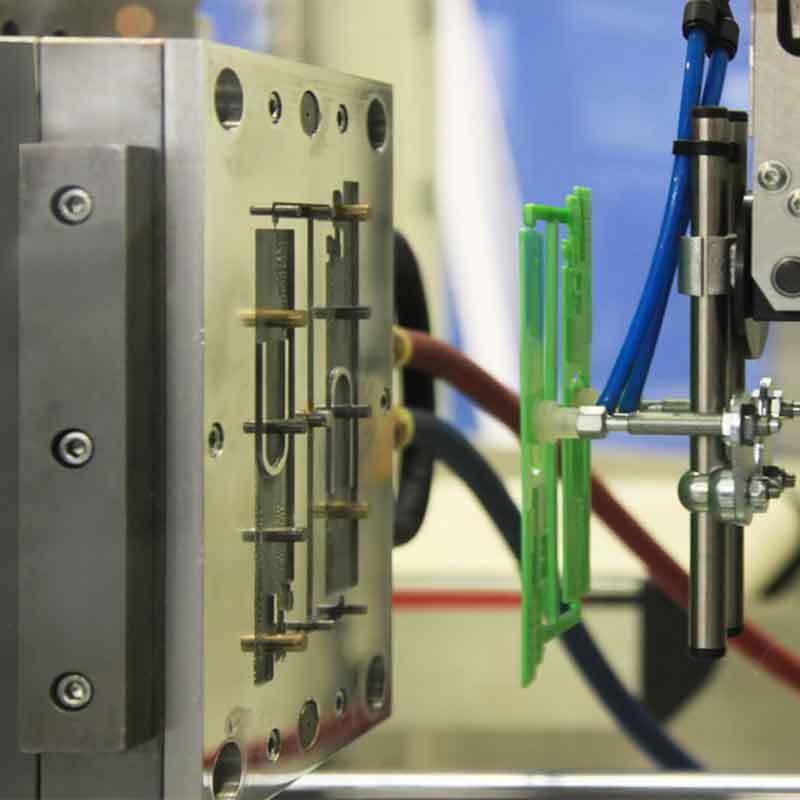

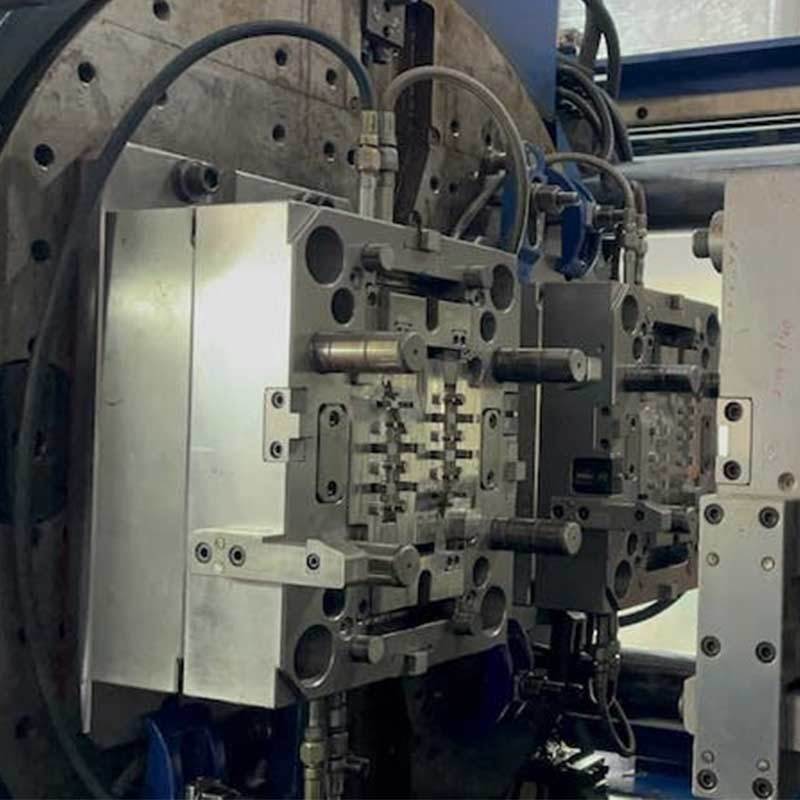

Silicone molds are made from liquid silicone rubber (LSR), cured using heat or a chemical catalyst to solidify into flexible, reusable molds.

Dive Deeper: From liquid to solid

Liquid Silicone Rubber (LSR)

LSR is a two-part mixture that cures quickly, enabling precision and consistency in mold creation.

Additives for enhanced performance

Manufacturers may add pigments, fillers, or stabilizers to improve mold durability and functionality.

Conclusion

Choosing the right materials for silicone injection molding or mold-making depends on your project’s specific needs. By understanding the properties and applications of these materials, you can make more informed decisions for your manufacturing processes.