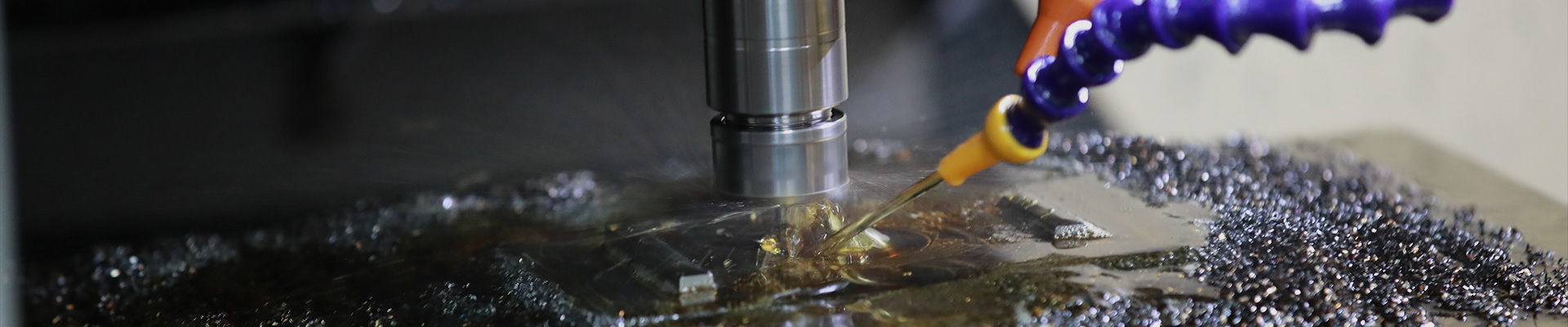

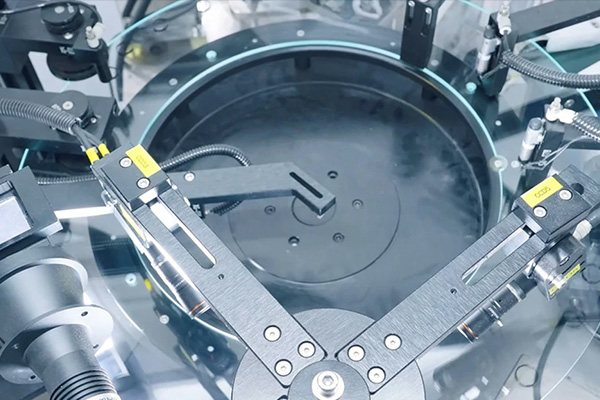

Advanced equipment

Equipped with internationally leading production equipment to ensure efficient and stable production.

Equipped with internationally leading production equipment to ensure efficient and stable production.

With experienced engineers and technicians, providing full technical support.

Implement a strict quality control system to ensure that every product meets the highest standards.

Constantly develop new processes and new materials to improve product performance and meet market demand.

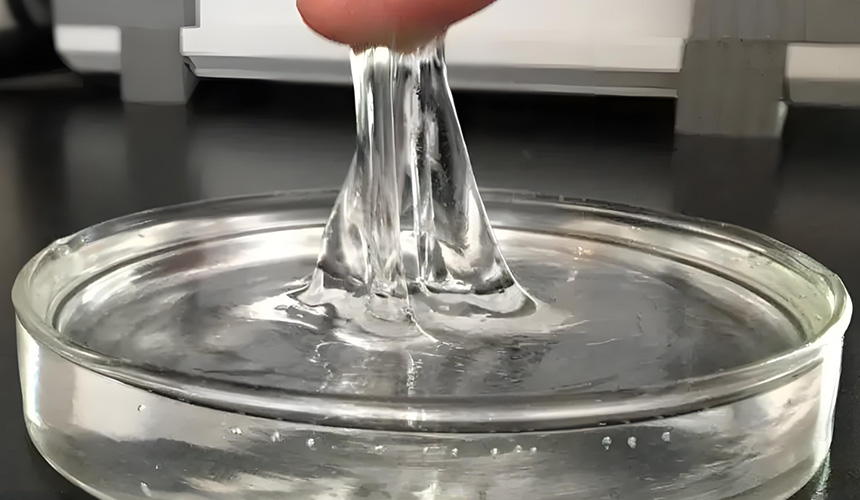

Our liquid silicone injection molding process is designed for mass production. Through high-precision injection molding equipment and advanced process control, we are able to achieve:

High efficiency:quickly produce large quantities of products, shorten delivery cycles, and meet market demand.

High precision:Each product is finely processed to ensure the consistency of size and performance.

High quality:Use high-quality liquid silicone materials to ensure that the product has excellent durability and stability.

For small batch orders, our liquid transfer molding process is the best choice. This process has the following advantages:

Flexible production:Ability to quickly switch molds and process parameters to meet the production needs of small batches and multiple varieties.

Cost-effectiveness:Reduce mold and material waste and reduce production costs.

High customization:Provide highly customized products according to customer needs to meet special specifications and functional requirements.

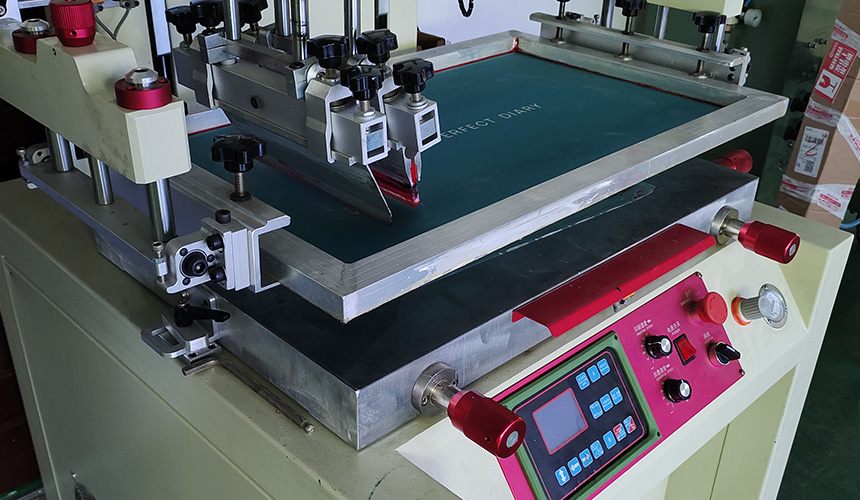

Our silicone product printing process uses advanced screen printing and digital printing technology to ensure that every detail is clear and exquisite.

Our UV spraying process uses advanced ultraviolet curing technology to provide high-quality surface coatings for silicone products, enhancing the protective performance and aesthetics of the products.

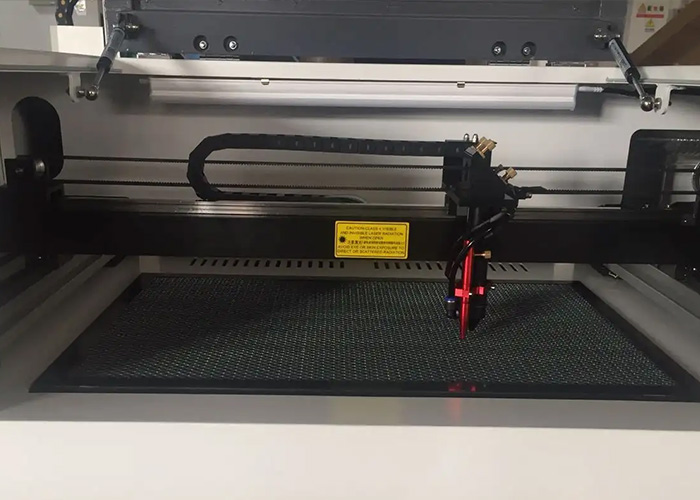

Our laser engraving process uses advanced laser engraving technology to engrave fine patterns and texts on silicone products, presenting a unique sense of technology and art.

Our laser engraving process uses advanced laser engraving technology to engrave fine patterns and texts on silicone products, presenting a unique sense of technology and art.

Our automated feeding system uses advanced mechanical and intelligent control technology to efficiently and stably deliver raw materials to the production line to ensure continuous and uninterrupted production.

Efficient and stable:The automated feeding system can greatly improve production efficiency, reduce manual operations, and improve the continuity and stability of the production line.

Intelligent control:Using an intelligent control system to monitor and adjust the feeding speed and quantity in real time to ensure the accuracy and stability of raw material supply.

Reducing waste:Effectively reduce the waste of raw materials, reduce production costs, and improve production efficiency.

Our automated dispensing system uses high-precision dispensing equipment, which can achieve precise and efficient dispensing operations during the molding process of silicone products to ensure the quality and consistency of each product.

High precision:The automated dispensing system can accurately control the amount and position of each dispensing to ensure the quality and consistency of the product.

High efficiency:The automated dispensing operation is fast, which greatly improves production efficiency and meets the needs of mass production.

Strong flexibility:The system can be flexibly adjusted according to the needs of different products to adapt to diverse production tasks.

Our automated quality inspection system uses advanced image recognition and sensing technology to automatically detect each product on the production line in real time to ensure stable and reliable product quality.

High precision:The automated quality inspection system can detect various parameters and indicators of the product to ensure that each product meets the highest quality standards.

Real-time detection:The system can detect products on the production line in real time, promptly detect and eliminate unqualified products, and ensure the quality of the products leaving the factory.

Data recording:Automatically record the inspection data of each product, provide complete quality traceability and analysis, and provide strong support for quality management.

Strict screening:We only use raw materials from high-quality suppliers to ensure the purity and stability of the materials.

Component analysis:Component analysis is performed on each batch of raw materials to ensure that the materials meet the specified chemical and physical indicators.

Incoming material inspection:Strict incoming material inspection is implemented, including appearance, size, hardness, tensile strength and other indicators to ensure the qualified rate of raw materials.

Standardized operation:Strictly follow the standardized operating procedures for production to ensure the standardization and uniformity of each link.

Equipment calibration:Regularly calibrate and maintain the production equipment to ensure the accuracy and stability of the equipment.

Process monitoring:During the production process, multiple monitoring points are set to monitor the production parameters and process conditions in real time to ensure the consistency and stability of the product.

Quality inspection:Quality management personnel regularly inspect the production site to promptly identify and solve potential problems and ensure the smooth progress of the production process.

Semi-finished product inspection:Semi-finished product inspection is carried out after the product is formed, including size measurement, appearance inspection, hardness test, etc., to ensure that the quality of semi-finished products meets the standards.

Process parameter recording:Detailed records of production parameters and process conditions for each batch of products to ensure product traceability and consistency.

Sample testing::Samples are taken for function and performance testing to ensure the reliability and stability of the product in subsequent use.

Combination of full inspection and random inspection:A combination of full inspection and random inspection of finished products ensures that each product meets quality requirements.

Multi-dimensional inspection:Including inspections of multiple dimensions such as size, appearance, hardness, tensile strength, and aging resistance to ensure the overall quality of the product.

Packaging inspection:Inspect the packaging of the product to ensure that the packaging is complete and firm to prevent damage during transportation.

Pre-shipment re-inspection:Final re-inspection before the product leaves the factory to ensure that all products meet customer requirements and relevant standards.

Random sampling:Random sampling of batch products to ensure the quality stability and consistency of large-scale products.

Test report::Issue a detailed test report and ship it with the product to make customers more assured of product quality.

Our customer service is online 24/7 to provide you with professional advice.

Based on your specific needs and project requirements, we will provide you with customized solutions to best meet your needs.

Free DFM reportContact us to quickly provide you with better silicone and plastic product prototypes.

Quick Quote