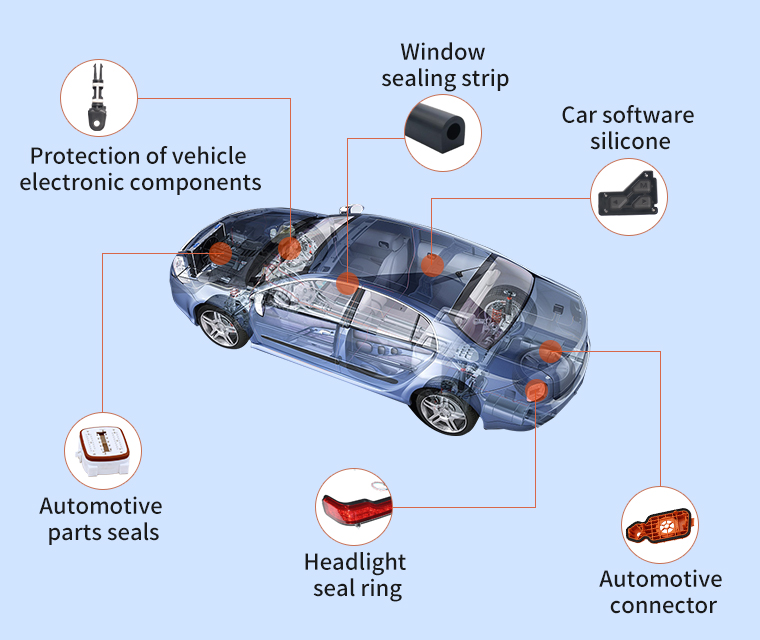

1. Material selection and formula customization

Based on the specific needs of the automotive industry, we select suitable silicone materials to ensure that they have excellent temperature resistance, aging resistance and chemical corrosion resistance. Our material scientists and engineers will customize the best formula according to different application scenarios to meet customers' high standards for performance and quality.

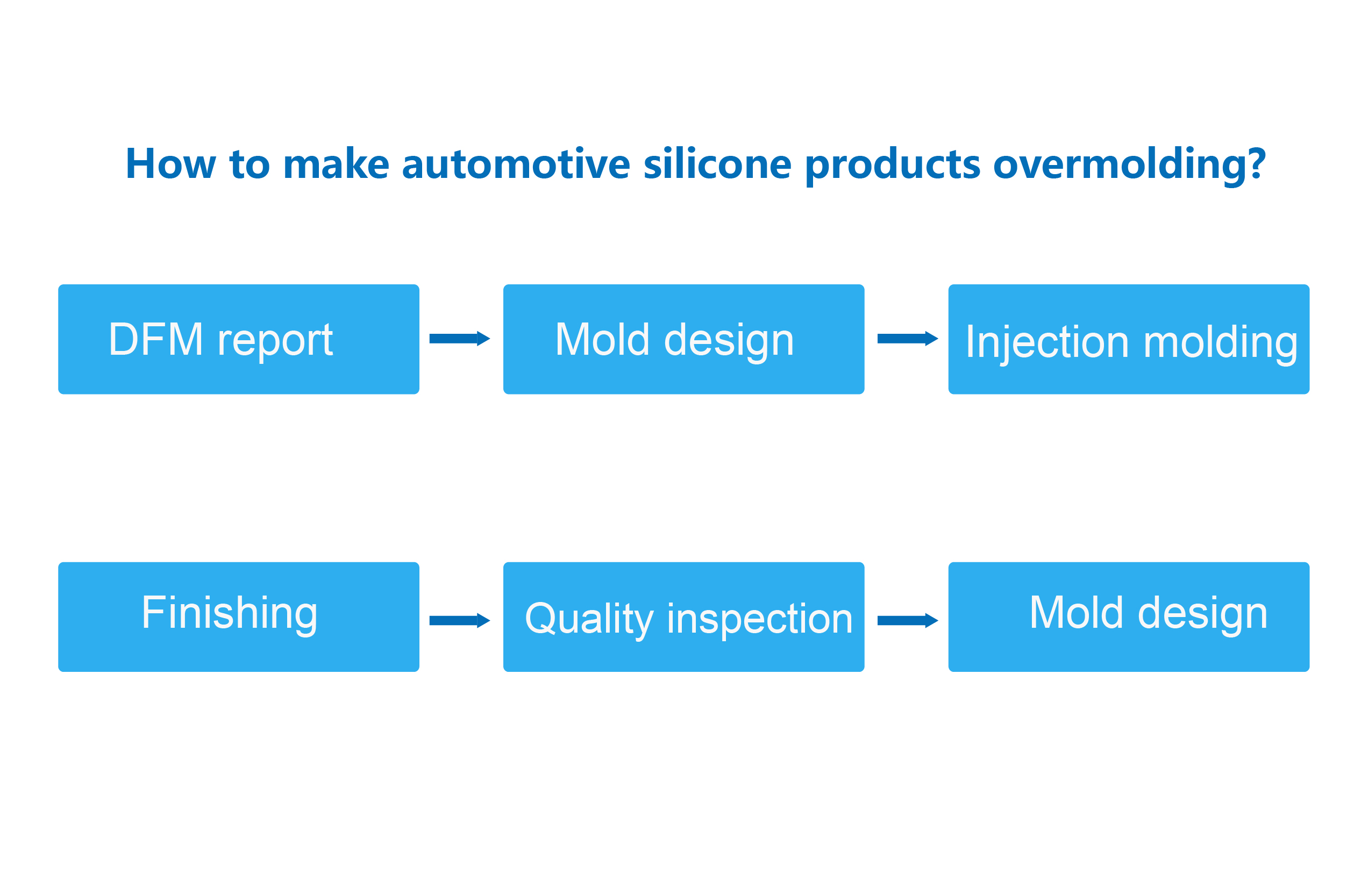

2. Precision mold development

The precision of the mold determines the quality of the final product. We use advanced CNC machining and EDM technology to design and manufacture high-precision molds to ensure that every detail of the silicone product meets strict tolerance requirements. During the mold development process, we maintain close communication with customers to ensure that the mold design meets the installation and use requirements of automotive parts.

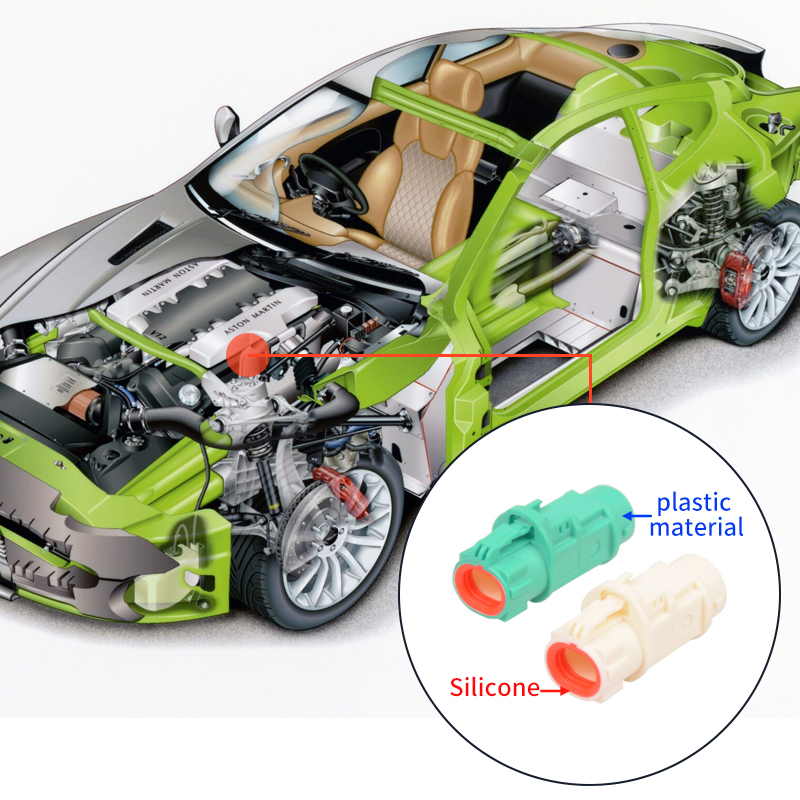

3. Molding process

For different automotive parts, we select the most suitable molding process, including liquid injection molding (LIM), compression molding and transfer molding. During the molding process, silicone is precisely molded into the required structure under heating and pressure to ensure that it can maintain stable performance under extreme temperature and pressure environments.

4. Post-processing and surface treatment

In order to enhance the performance of silicone products, we perform necessary post-processing on the molded products, such as removing flash, polishing, coating, etc. These steps not only improve the appearance of the product, but also enhance its durability and weather resistance, ensuring its long-term use in harsh automotive environments.

5. Quality Inspection and Control

Every silicone product undergoes strict quality inspection before leaving the factory. We use advanced testing equipment to conduct multiple performance tests such as size, hardness, tensile strength, etc. to ensure that the products meet the stringent standards of the automotive industry. Through sophisticated testing processes, we are able to provide silicone parts with reliable quality and stable performance.

6. Packaging and Logistics

In order to ensure the safety of products during transportation and storage, we use professional packaging solutions to ensure that silicone products remain in perfect condition when they reach customers. Our efficient logistics network can deliver on time to meet customers' urgent needs.