Home / All / Silicone Overmolding Products / 3C Electronics Silicone Overmolding / Mobile phone waterproof solution /

Injection molding liquid silicone one-piece molding hardware mobile phone PIN needle silicone waterproof PIN needle silicone rubber metal factory

Injection molding liquid silicone one-piece molding hardware mobile phone PIN needle silicone waterproof PIN needle silicone rubber metal factory

| Categories | Mobile phone waterproof solution |

|---|---|

| Brand | SiliconePlus | Silicone OverMolding Manufacturing |

| color | Customizable |

| Update Time | Apr 25,2025 |

Detail Information

Product Usage Scenarios

For hardware mobile phone PIN needle waterproof rubber coating products, customers in the market usually face the following common pain points.

1. Waterproof effect is not up to standard

Pain point: When waterproofing, the hardware mobile phone PIN pin products on the market often fail to meet the IP67 or IP68 waterproof grade standards due to insufficient encapsulation, which affects the stability of the product in a humid environment.

Solution: Siliconeplus uses high-precision silicone injection molding encapsulation technology to ensure that the silicone of each PIN pin interface is tightly combined with the substrate, has excellent waterproof performance, and strictly passes the waterproof test to meet the industry's high standards.

2. Silicone and metal are not firmly bonded

Pain point: The silicone and the metal surface of the hardware PIN pin are not firmly bonded, resulting in the encapsulation of the product falling off during use, which in turn affects the waterproof performance and service life.

Solution: Siliconeplus uses professional surface treatment and silicone encapsulation technology to ensure the firm bonding of silicone and metal surfaces, ensure the durability and bonding strength of the product in various environments, and effectively improve the service life of the product.

3. Dimensional accuracy and consistency are not up to standard

Pain point: Customers require PIN pin products to have extremely high dimensional accuracy and consistency in mass production, but many suppliers in the market find it difficult to ensure accuracy during mass production, resulting in poor contact or mismatching during assembly.

Solution: Siliconeplus has advanced production equipment and its own mold room, which can accurately design and process molds to ensure the consistency and high precision of products in mass production, so that the PIN pin interface can perfectly match various electronic devices.

4. Difficult demoulding and surface damage

Pain point: It is difficult to demould products during production, which can easily cause surface damage and affect the appearance and performance of the products. Especially in 3C electronic products, the appearance quality is also an aspect that customers focus on.

Solution: Siliconeplus adopts high-quality mold design and optimized demoulding technology to ensure that PIN pin products can be demoulded smoothly, maintain surface finish and integrity, and avoid defects in the demoulding process that affect product quality.

5. Waterproof encapsulation affects conductivity

Pain point: Since the PIN pin needs to have good conductivity, improper silicone encapsulation may cause the product's conductivity to be damaged or poor contact, affecting the use of the final device.

Solution: Siliconeplus uses precise encapsulation technology to protect the conductive parts during encapsulation to ensure that the conductivity of the PIN pin will not be affected by the encapsulation, thereby ensuring the stability and efficient conductivity of the product.

6. Long delivery cycle affects market response

Pain point: In the electronics industry, product updates and iterations are fast, and customers need suppliers to respond to orders quickly, but many suppliers in the market are not efficient enough in production processes, resulting in long delivery cycles, affecting customers' market response speed.

Solution: Siliconeplus has greatly shortened the production and delivery cycle through its own mold room and integrated production capacity. We can complete mold opening, proofing, and mass production in a short time after confirming the order, ensuring that customers can quickly obtain the required products to cope with changes in market demand.

7. Complex process leads to high production cost

Pain point: The production process of waterproof encapsulation is complex, especially for the fine encapsulation of metal PIN pins. Many suppliers lack effective process control, which leads to rising costs and affects customers' price competitiveness in the market.

Solution: Siliconeplus optimizes the encapsulation process, utilizing Injection Molding Liquid Silicone to enhance material efficiency and reduce production costs while ensuring product quality. This helps customers improve price competitiveness without compromising on quality.

Siliconeplus, with its professional process and extensive production experience in Injection Molding Liquid Silicone, effectively addresses the pain points in waterproof encapsulation for hardware mobile phone PIN pins, delivering high-quality, stable, and reliable customized solutions to enhance customers' market competitiveness and product performance."

Advantages and features of the product:

1. High-precision injection molding technology

Precision manufacturing: Our injection molding technology enables high-precision processing of liquid silicone, and even complex geometric shapes or extremely small details can maintain excellent molding effects to meet the needs of different application scenarios.

Seamless products: Liquid silicone (LSR) injection molding is used to produce products with seamless and integrated molding characteristics, ensuring excellent performance in strength, durability and aesthetics.

2. Multi-material combination

The combination of silicone and other materials: One of the major advantages of Siliconeplus is the ability to combine silicone with materials such as metal, plastic, FPC, etc., providing higher functionality and a wide range of customization options. This multi-material fusion is suitable for a wide range of applications in industries such as medical, electronics, and consumer products.

Strong bonding technology: Our unique bonding technology for silicone and other substrates ensures a strong bond between silicone and metal or plastic substrates, enhancing the durability and service life of the product.

3. Excellent material properties

High temperature and low temperature performance: Liquid silicone has excellent high temperature resistance (up to 300°C) and low temperature performance, suitable for use in extreme environments, especially for applications that require high temperature resistance or freezing.

Anti-aging and chemical stability: Silicone has excellent anti-aging, UV resistance and chemical stability, ensuring that the product maintains stable performance for a long time in various harsh environments.

Biocompatibility and non-toxicity: We use medical-grade liquid silicone, which is highly safe, non-toxic and non-allergenic, especially suitable for industries with extremely high safety requirements such as medical devices and baby products.

4. Efficient customization and flexible design

Highly customizable: We can customize liquid silicone products of different shapes, sizes and hardness according to the specific needs of customers, and support customers' brand logos or specific functional designs.

Diverse color and appearance options: Siliconeplus's production process can support a variety of colors and surface treatments for silicone products to meet the market's customized needs for product appearance and functions.

5. Advanced production equipment and large-scale production capacity

Automated production line: We have advanced automated injection molding equipment to ensure efficient and stable production processes, and can cope with the needs of large-volume orders while maintaining excellent quality.

Shorten delivery cycle: Our strong production capacity and effective process management can quickly respond to market demand, shorten product delivery cycles, and ensure that customers occupy a favorable position in the fierce market competition.

6. Strict quality control and certification

Quality assurance: We implement a strict quality control system to ensure that every injection molded liquid silicone product meets international standards and undergoes a series of durability and functional tests to ensure that it meets high-standard application requirements.

International certification: Our production processes and materials comply with quality system certifications such as ISO 9001 and ISO 13485, ensuring that the liquid silicone products produced are suitable for high-demand scenarios in various industries.

7. Innovation and technical support

Continuous innovation: Siliconeplus is committed to continuous innovation in liquid silicone injection molding technology, providing more cutting-edge solutions to help customers gain a competitive advantage in the market.

Technical support: We provide full technical support from product design to production to ensure that customers' projects get professional solutions from concept to finished product.

Through these advantages, Siliconeplus is able to provide customers with high-performance, flexible customization, and durable liquid silicone products to help customers stand out in various industries.

Siliconeplus Waterproof advantage

After silicone encapsulation, our products can reach IP68 waterproof level, which means that it can be used for a long time underwater up to 1.5 meters deep while completely preventing dust intrusion. This high level of waterproof performance allows the product to work stably in various extreme environments, and is particularly suitable for application scenarios that require waterproof and dustproof protection, such as outdoor equipment, smart wearable devices, medical equipment, and industrial controllers.

In addition, the sealing of silicone encapsulation not only improves the waterproof performance, but also significantly improves the durability and protection of the product. Whether in humid, high temperature, low temperature or dusty environment, the product can still maintain good functional performance. Combined with the anti-aging, corrosion resistance and high temperature stability of silicone, this design can extend the service life of the equipment, reduce maintenance costs, and improve overall reliability.

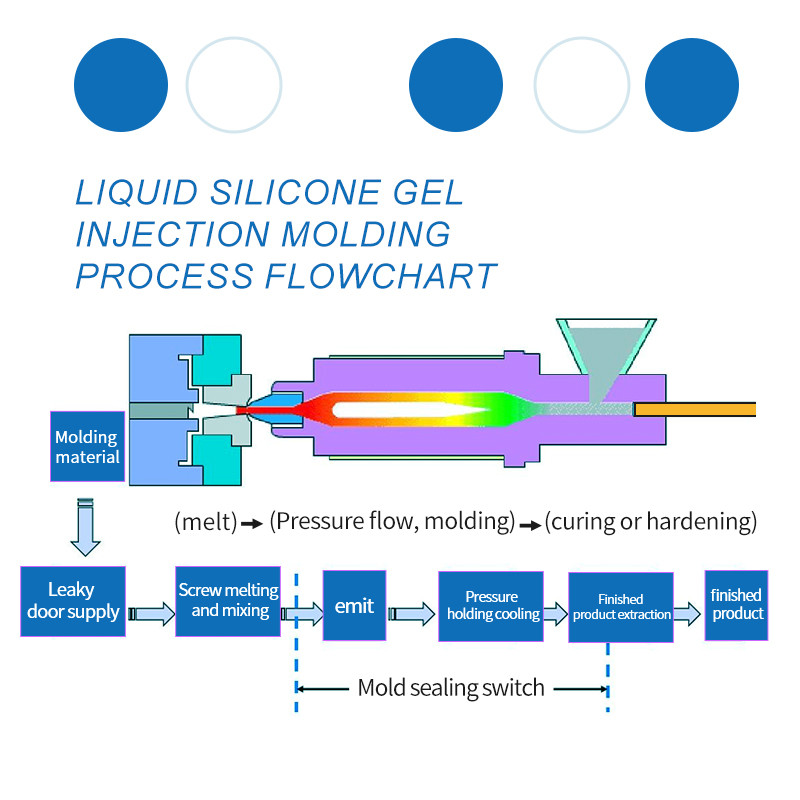

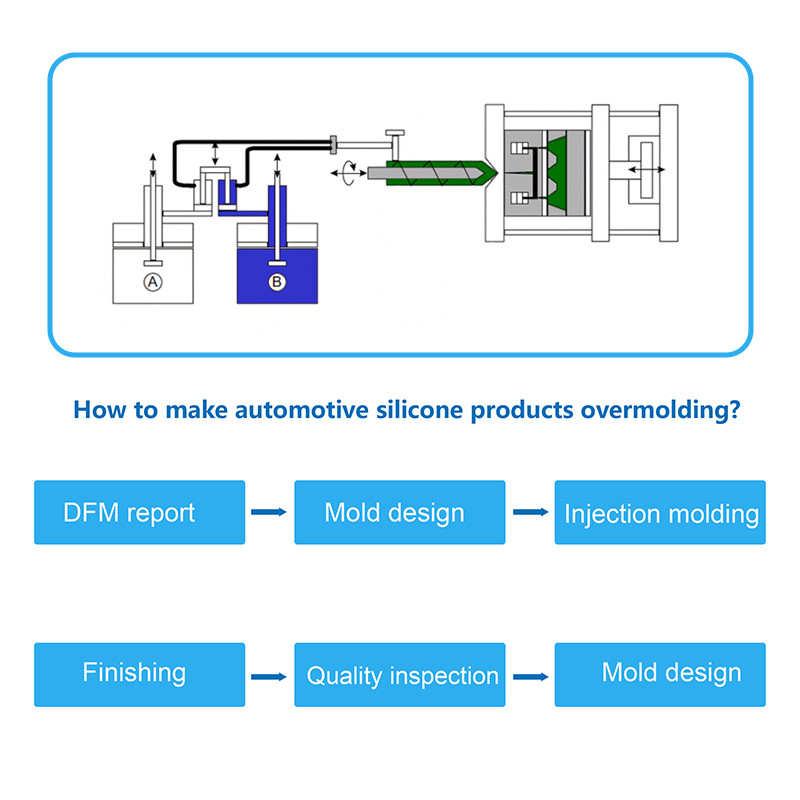

Production process

Custom FAQ

Can the product's waterproof performance meet IP67 or IP68 standards? Can it guarantee stable functionality in a specific water depth and environment?

Siliconeplus uses a sophisticated encapsulation process to ensure that the waterproof level reaches IP68 and can work stably underwater up to 1.5 meters deep.

Are the silicone and the metal substrate of the PIN firmly bonded? Will there be debonding or cracking during use?

We use professional surface treatment technology and bonding technology to ensure that the silicone and the metal substrate are firmly bonded, and the product can maintain high stability in various environments without debonding problems.

In mass production, how to ensure the dimensional consistency of products and ensure perfect matching with equipment?

Siliconeplus relies on its own mold room and precision mold manufacturing equipment to ensure the dimensional accuracy and product consistency of mass production through strict quality control processes, avoiding poor contact and mismatching problems.

Will the product surface be damaged during the demoulding process? How to ensure the surface quality of the PIN needle encapsulated product?

We use optimized mold design and efficient demoulding technology to ensure that the product is smoothly and damage-free during the demoulding process, while maintaining the surface finish to meet the appearance quality requirements of 3C electronic products.

Will silicone encapsulation affect the conductivity of the PIN? Will there be a problem of poor contact?

Siliconeplus uses precise encapsulation technology to ensure that the conductive area is not affected. Our production process provides special protection for the conductive parts to ensure the conductivity of the PIN and stable signal transmission.

Related Products

Review

- Loading...

Please send your message to us

- *Tel

- *Title

- *Content

Contact Person

- Name:

- Miss Yang

- Tel:

86-13420974883

- Email:

- sale11@lyasilicone.com

- WhatsApp:

- https://wa.me/8613424186971

- Skype:

- Skype:8613420974883