Home / All / Silicone Overmolding Products / Medical Grade Silicone Overmolding /

Professional Silicone Overmolding Factory | ISO-Certified Manufacturer

Professional Silicone Overmolding Factory | ISO-Certified Manufacturer

| Categories | Medical Grade Silicone Overmolding |

|---|---|

| Brand | SiliconePlus | Silicone OverMolding Manufacturing |

| Bonding Strength | peel strength exceeding 10N/mm |

| Durability & Chemical Resistance | -50°C - 250°C |

| Update Time | Apr 25,2025 |

Detail Information

Are you looking for high-precision silicone overmolding with strong adhesion to plastic or metal? Our custom overmolded silicone parts offer waterproof, dustproof, and chemical-resistant properties, making them ideal for medical devices, automotive components, and industrial applications.

Our silicone overmolding process ensures seamless bonding to PC, ABS, stainless steel, aluminum, and other materials. We provide:

Custom OEM Overmolding – Tailored to your design & specifications.

High Durability – Resistant to high temperatures, chemicals, and mechanical stress.

Medical-Grade & Industrial-Grade – Compliant with FDA, ISO 13485 & RoHS.

Fast Turnaround & Low MOQ – Get your prototype ready in as fast as 7 days.

✅ Case 1: Medical-Grade Silicone Overmolding

Customer requirements: Medical-grade cable connectors need to be IP68 waterproof, high temperature resistant, and FDA compliant

In the medical industry, connectors for electronic devices must be waterproof, dustproof, high temperature resistant, and able to withstand high-frequency sterilization (such as high temperature and high pressure sterilization, chemical cleaning, etc.). In addition, the connector material must be biocompatible and will not release harmful substances that affect the safety of the medical environment.

Specific requirements:

✔ IP68 waterproof and dustproof to ensure normal use in humid or liquid environments

✔ High temperature resistant (>150°C), supports high temperature sterilization (such as high pressure steam sterilization or EtO gas sterilization)

✔ Soft and durable, not easy to break, to meet the needs of long-term bending use

✔ Comply with FDA & ISO 10993 standards to ensure medical safety

Solution: Use Liquid Silicone Rubber (LSR) Overmolding to ensure strong adhesion and seamless protection

We use liquid silicone (LSR) overmolding technology to inject liquid silicone directly into the plastic or metal part of the cable connector through a high-precision mold to form a seamless sealing layer.

Technical advantages:

✔ High-strength bonding: No additional adhesive is required, it is directly chemically bonded to the substrate to prevent falling off

✔ Seamless one-piece molding: Eliminate gaps, prevent liquid penetration, and improve IP68 protection level

✔ Medical grade silicone: Use FDA-certified LSR, which meets ISO 10993 biocompatibility standards

✔ High temperature tolerance: Can withstand high-pressure steam sterilization (Autoclave 121°C) without deformation or release of harmful substances

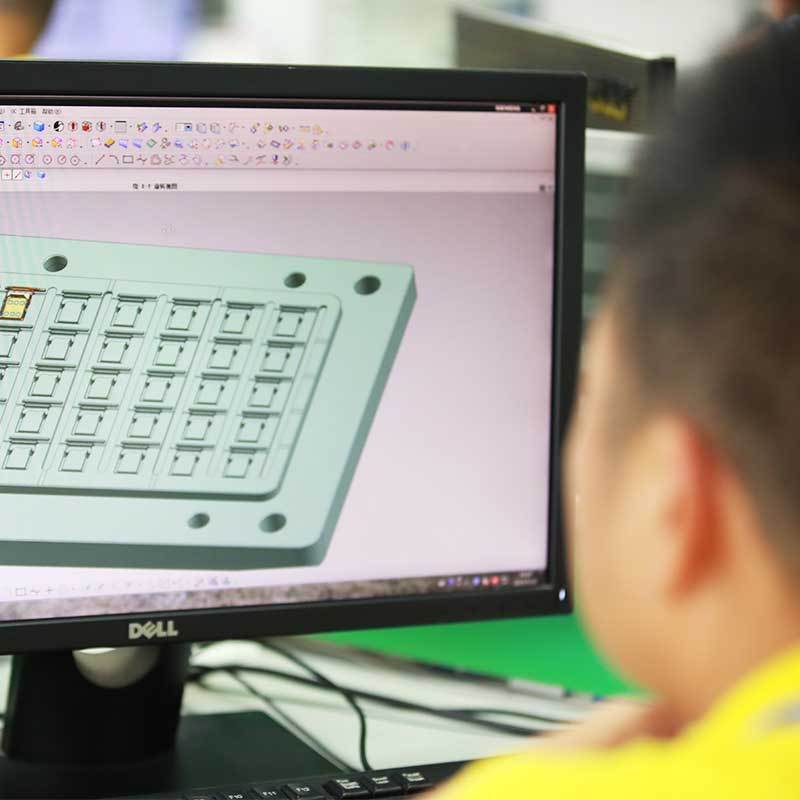

✅ Case 2: PC/ABS + Dual-Shot Molding for Industrial Silicone Keypads

Customer requirements: The production of industrial equipment keys requires anti-slip, wear-resistant, and comfortable feel

The control panels and keys of industrial equipment are often faced with high-frequency operations, oil, dust, and extreme environments. Customers hope to find a material combination solution that can ensure durability and provide a comfortable touch.

Specific requirements:

✔ Anti-slip surface, improve the operating feel, and can be easily operated even with gloves

✔ Wear-resistant & chemical-resistant to ensure long-term use without damage

✔ Customizable colors, clear and visible logos, and improve user experience

✔ Accurate size to ensure a perfect match with the equipment

Solution: PC/ABS hard plastic + silicone overmolding to provide precise dimensions and long-term durability

We use two-shot molding / overmolding technology to integrate PC/ABS hard plastic and silicone to form a strong + soft combination structure.

Technical advantages:

✔ Anti-slip silicone surface: optimizes the operating feel and improves anti-slip performance

✔ High durability: withstands 500,000 press tests and does not deform after long-term use

✔ Chemical corrosion resistance: can resist oil, solvents, and alcohol cleaning, suitable for industrial environments

✔ Precise size: ±0.02mm accuracy to ensure that the buttons fit perfectly with the circuit board

Application scenarios: widely used in consumer electronics, automotive central control, and industrial control panels

Our PC/ABS + silicone double-injection molded buttons are currently widely used in the following industries:

✅ Industrial equipment control panels (such as CNC machine tools, smart warehousing terminals)

✅ Automotive interior buttons (such as central control screen buttons, window lift switches)

✅ Consumer electronics (such as smart speakers, remote control buttons)

💡 Customer feedback:

"These overmolded keypads are much more durable than traditional rubber buttons. They resist wear, provide excellent tactile feedback, and fit perfectly into our industrial machines." – A North American industrial equipment manufacturer"These overmolded keypads are much more durable than traditional rubber buttons. They resist wear, provide excellent tactile feedback, and fit perfectly into our industrial machines." – A North American industrial equipment manufacturer.

Related Products

Review

- Loading...

Please send your message to us

- *Tel

- *Title

- *Content

Contact Person

- Name:

- Miss Yang

- Tel:

86-13420974883

- Email:

- sale11@lyasilicone.com

- WhatsApp:

- https://wa.me/8613424186971

- Skype:

- Skype:8613420974883